One thing AM investors keep telling is that, cash could “easily” be made available to those who will explore the applications enabled by AM. A couple of successful examples of vertically integrated businesses enabled by AM include Conflux Technology, MetShape, LightForce Orthodontics or even Additive Drives GmbH.

ECL, a Data Center-as-a-Service startup is the latest to join this cohort with a $7M seed funding from Molex Ventures and Hyperwise Ventures. Its ambition? Building its first data center at the company’s Mountain View, Calif. headquarters, with completion scheduled for Q2 2023.

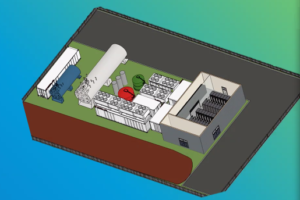

Optimized for use by mid-sized data center operators – typically large companies with a mix of cloud and on-premises IT environments – ECL’s Datacenter-as-a-Service is two-thirds the total cost of ownership (TCO) of traditional colocation data center providers when measured over five years. The community-integrated data center design consumes no local resources, including power or water, and operates with zero emissions at extremely low noise levels. ECL’s modularity and lack of dependence on local utilities also means that its data centers can be designed and delivered much faster than others’, reducing planning and construction cycles from between 18 to 24 months to between six and nine months, the company explains.

While other data center providers have deployed hydrogen fuel cells as backup power supplies, and with some conducting trials of systems forecast for production delivery in three-to-five years, ECL would be the first provider to deliver a fully-green hydrogen-powered data center. This leapfrog innovation is enabled by bringing together several disruptive technologies including green hydrogen-based power generation, battery energy storage and highly reliable power architecture without dependence on the utility grid. This maximizes efficiency and time to delivery and all but eliminates waste.

Among the technologies leveraged, ECL will rely on a construction 3D printer and the support of a local building services company. While the exact type of 3D printing technology has not been revealed, the company said in an interview with Data Center Dynamics that each 1MW unit will be built on demand using a 3D construction printer working with environmentally-friendly building materials. It will be powered by hydrogen fuel cells, supplied from an on-site tank filled by a local hydrogen supplier.

We also learned that construction 3D printers would be good fit for data centers, if they are small, which suits ECL’s modular design.

“We can print blocks one at a time, using sustainable concrete, with zero waste. When there is no construction on a site, ECL plans to offer the construction printer to the local community to make housing or community buildings: There’s no reason for us to sit on the printer“, ECL founder and CEO Yuval Bachar said.

After the initial building, ECL will own its own 3D printers and train staff up to use them: “We don’t need to have a construction company. The printer is operated by three people. That’s all you need to actually print a building: three people“, Bachar adds.

Cooling Innovations & ECL Lightning™ Data Center Management Platform

ECL cooling innovations enable much higher density-per-rack than traditional data center providers, a strong benefit given the increasing per-server power consumption driven by accelerating chip and system density. Water created as a by-product of hydrogen-based power generation is used to cool ECL’s server racks, eliminating the need for external water sources. Combining this with proprietary rear door heat exchange technology results in lower Power Usage Effectiveness (PUE) ratios than any other colocation data center provider.

Last but not least, ECL data centers feature an advanced full data center management system – ECL Lightning™ – which is used to monitor and control every aspect of the ECL data center, from power generation to power delivery and rack cooling, in real time. Its unique and intuitive UI provides comprehensive, clear and simple monitoring, which enables finite control of all aspects of operating the data center.

As you can see here, AM does not only play a role in driving hydrogen fueled gas turbines, it can also be pivotal in enabling a hydrogen powered data center.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com