According to the World Wildlife Fund, over 1.1 billion people do not have access to water and approximately 2.7 billion experience instances of water scarcity. As part of the AIR2WATER project, GE Research will play its part in addressing this issue.

Selected by DARPA – the Defense Advanced Research Projects Agency, the technology development arm for the General Electric Company (GE) has been granted $14.3 million to achieve the four-year ambitious project.

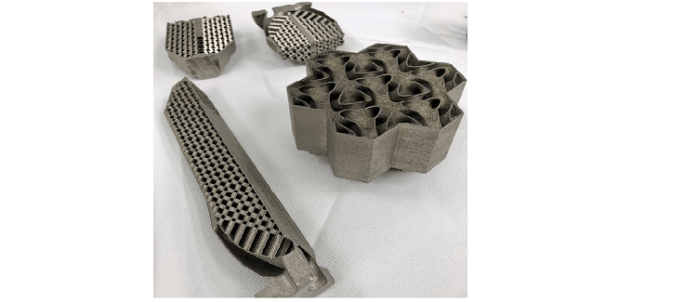

AIR2WATER stands for Additively Manufactured, Integrated Reservoir To Extract Water using Adsorbents and Thermally-Enhanced Recovery. The project is part of the Atmospheric Water Extraction (AWE) program, a program that aims to develop scalable sorbent materials that can rapidly extract water from ambient air and leverage advanced modeling, innovative engineering, and additive manufacturing methods to achieve a substantial reduction in the size, weight, and power (SWaP) requirements compared to current atmospheric water generation technologies.

In other terms, for the multidisciplinary team at GE Research, this mean developing new distributed systems to reduce risks and costs associated with delivering potable water to troops in the field and for humanitarian missions.

Indeed, the transport of clean, safe water today can involve air and ground vehicle transport over long distances and complex terrain. This contributes to logistics burden of one third of the Department of Defense budget. Furthermore, 10-12% of USMC causalities in Iraq and Afghanistan were due to the moving of fuel and water, according to the AEPI Report.

David Moore, the Principal Investigator and Technology Manager for Material Physics and Chemistry at GE Research, says the development and deployment of such a device would transform military transport operations involving water, stating, “Today, the logistics and costs involved with transporting water are staggering and in dangerous war zone areas, result in casualties. By creating a highly portable, compact device that efficiently extracts water from the atmosphere, we can save lives and ease the logistical and financial burden for our armed forces.”

Currently, GE Research is developing a prototype that would drastically reduce or potentially eliminate the need for the distribution of water by providing a ready source of clean water directly where troops are stationed.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com