Tooling & Equipment International (TEI), an expert in design, engineering and manufacturing of prototype, pre-production and mass production equipment for the casting industry, is according to machine manufacturer voxeljet, one of the largest users of 3D sand printing in the US.

As a supplier to General Motors, the company uses this technology for the production of new, function-optimized designs. As part of a project, the company uses the VX4000 3D sand printers from voxeljet, to produce cast cores for the series production of large-format, weight-saving structural components for the Cadillac CELESTIQ.

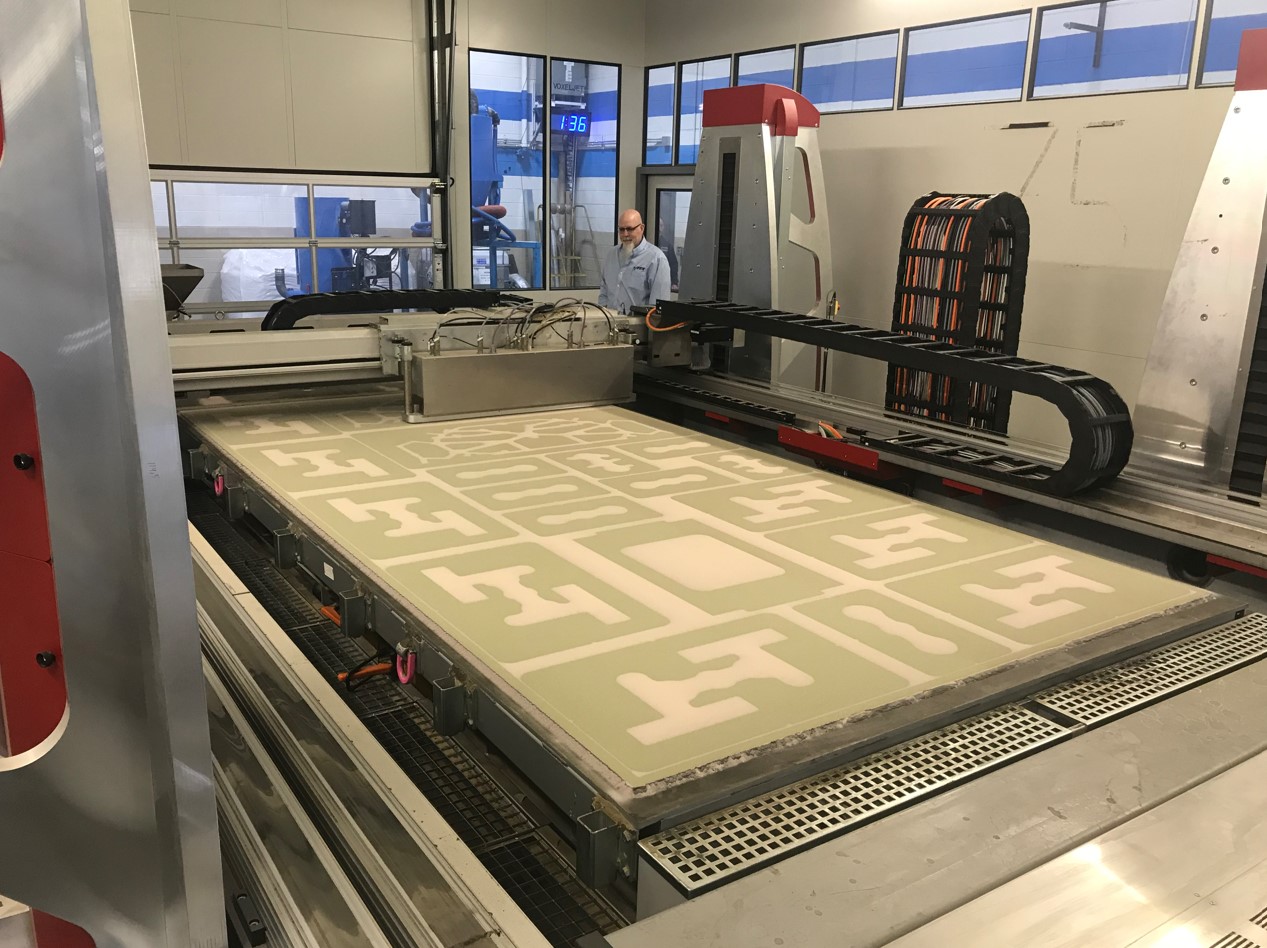

The novel underbody structure consists of six large precision sand-cast aluminum parts. In order to realize the complex structures as economically and lightly as possible, TEI uses additive manufacturing in production for all inner cores, a press release explains. With a build volume of 4 x 2 x 1 meters and three 3D printers in-house, the team could produce hundreds of inner cores for several vehicle sets in just one night.

The manufacturing process allows stiffening features to be incorporated into the hollow sections, which is not economically feasible with conventional manufacturing. A total of 51 additively manufactured sand cores are used in the production of each vehicle underbody.

After printing, the cores are smoothed, coated with a fireproof coating, placed in sand molds and finally cast using a low-pressure filling process. Each of the six castings reduces the number of parts by 30 to 40 components compared to a typical stamped construction. As each structural part has fully machined interfaces, the six castings can be assembled precisely and very tight tolerances can be maintained for assembly fabrication.

After printing, the cores are smoothed, coated with a fireproof coating, placed in sand molds and finally cast using a low-pressure filling process. Each of the six castings reduces the number of parts by 30 to 40 components compared to a typical stamped construction. As each structural part has fully machined interfaces, the six castings can be assembled precisely and very tight tolerances can be maintained for assembly fabrication.

“By eliminating tools and taking advantage of the large build volume of the VX4000 printers, we can significantly reduce delivery times and produce lightweight components with optimized topologies. This would not be possible in the conventional way,” explains Oliver Johnson, President of TEI.

Last but not least, 3D sand printing makes completely new designs and light weight structures possible. This results in geometrically optimized parts, which are very important for the automotive and aerospace industries.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com