STILRIDE – the Swedish startup known for its origami-inspired approach to electromobility design and manufacturing – is working with French-Swedish robotics company ADAXIS to simplify the production process of its electric motorbike.

ADAXIS is part of the exhaustive list of start-ups that have been created in the midst of the pandemic. They turned stealth mode off last year by securing 1 million euros in pre-seed funding from EIT Manufacturing, Newfund Capital, SkalePark and regional grants. At the heart of its business model, lies the development of a software platform that enables to transform and program commercially available industrial robots as flexible manufacturing cells based on 3D printing.

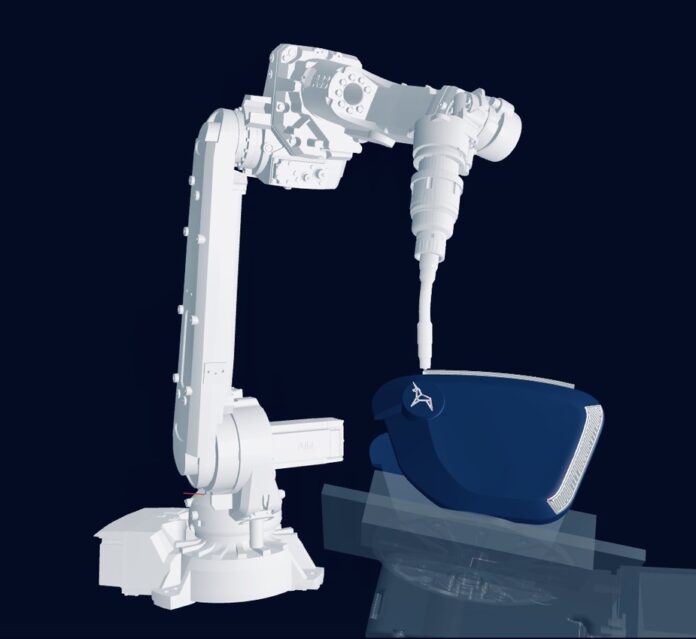

STILRIDE’s technology, called STILFOLD, involves the use of robotic arms to fold steel over curves to form light and strong new structures, using minimal component parts. The technology is currently being used to build the chassis of a sustainable steel electric motorbike called the Sport Utility Scooter One (SUS1) which is built using 70% fewer components than traditional plastic models.

Until now, STILRIDE has had to source a number of component parts for the SUS1’s early prototypes – such as hinges, fenders and side covers – from external suppliers. These are small and complicated parts that STILRIDE’s engineers cannot create using STILFOLD.

But the new partnership with ADAXIS means STILRIDE will be able to produce a number of these complex components out of steel using additive manufacturing. ADAXIS’s software enables engineers to programme a robotic arm to 3D print large and complex steel, plastic, composite and concrete parts quickly, whilst significantly reducing costs and material waste. Damaged parts can also be repaired efficiently using the same technology.

The partnership also brings new additive manufacturing capabilities to STILRIDE’s existing suite of manufacturing technology, called STILFOLD, which will eventually be made available to designers and manufacturers who wish to licence it to build their own work.

“Using robotization we can push the limits of what can be manufactured using 3D technology, both in terms of size and shape. The challenge is that programming robots for 3D is significantly more advanced and complex than for normal welding jobs. Our goal is to speed up the manufacturing process and make it more intuitive, even when it comes to really complex projects, so that everyone can benefit from this technology, Emil Johansson, co-founder at ADAXIS, comments.

Already, the STILFOLD technology is being used by Polestar to develop the world’s first climate neutral car; and by Swedish space innovation agency I.S.A.A.C to explore how curve folding could be used for construction in outer space.

“Not only will [ADAXIS]’ technology improve the sustainability, speed and cost-efficiency of producing the SUS1, but it will also help us reach our ultimate goal of rolling out a fully distributed production model where the construction of our products can be fully automated, powered by robotics technology”, Jonas Nvyang, CEO and co-founder at STILRIDE, comments.

Remember, you can post jobopportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com