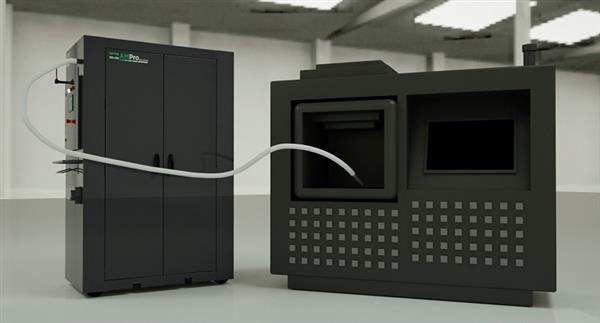

Russell AMPro Sieve Station™ is a powder management system that is used in metal 3D printing and that ensures that the materials are employed efficiently.

In addition to ensure the quality of the additive manufacturing powder (which implies the use and the reuse of the powder), Russell AMPro Sieve Station™ aims at providing optimum sieving efficiency.

The powder management system has been manufactured by Russel Finex, specialist in designing and manufacturing vibratory sieves, separators, ultrasonic mesh deblinding systems and liquid filters for use throughout the processing industries.

The importance of a powder management system

A powder management system is essential for metal additive manufacturing machines.

Indeed, its first role is to qualify incoming powders for the 3D printing process, and after requalifying these powders, its second role is to recycle the unused material after the print.

The truth is that it would have been very costly and time-consuming to use a new metal powder bed at the end of every print. However, using the same metal powder bed can lead to contaminated materials, or deteriorate the unused powder parts.

Such a powder management system is therefore mandatory to enable an efficient metal AM process.

According to the company,with a one-button operation and mobile design, the automated check screener ensures your powder at every stage of the process is qualified for use quickly and safely. The flexibility of the Russell AMPro Sieve Station™ means you can use the system for numerous powder handling tasks – being a modular design ensures the machine can be configured to meet your exact requirements.

Last, the design of the Russell AMPro Sieve Station can be adapted to the requirements of users at any step of the 3D printing industry, whether start-up or full-scale production. It can work with powder vessel transfer, or as part of a closed-loop powder recovery system.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});