PIP stands for Profilometry-based Indentation Plastometry. It’s a technology developed by Plastometrex, a provider of mechanical testing solutions, headquartered in the UK who claims testing of 3D printed metal parts “could easily be 99% more efficient.”

With their PIP technology, it aims to address the current limitations of conventional testing methods (like tensile testing) which come with significant time and cost implications.

In an AM process, “the time and material required to produce tensile coupons take up significant chunks of project timelines and budgets, while the use of separately printed tensile coupons often fails to fully represent the mechanical properties of complex additively manufactured parts, potentially affecting the reliability of data,” Plastometrex explains.

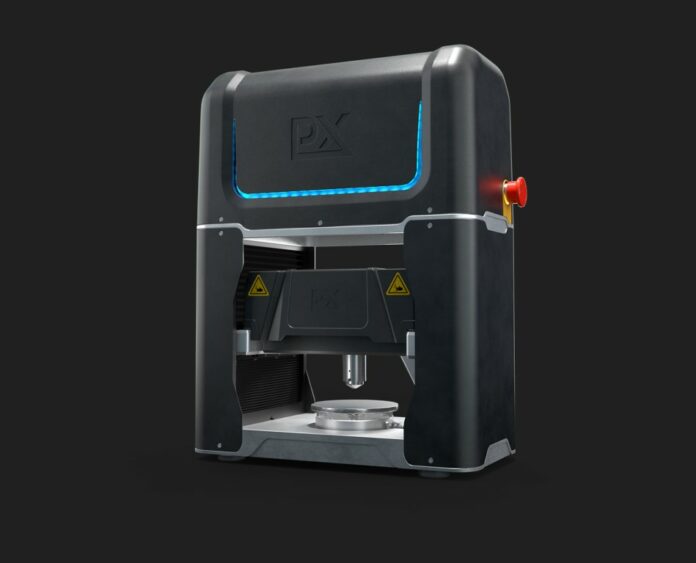

To address these challenges, the company’s LX-Benchtop facilitates rapid, direct testing on different sections of 3D printed parts, delivering stress-strain curves in minutes. AM OEM Renishaw will test the capabilities of this solution as it will incorporate Plastometrex’s proprietary PIP into its testing processes.

Benjamin Haigh, Materials Scientist at Renishaw, commented: “We can now use cubes built for product development for additional testing, saving us time and money. Additionally, the PLX-Benchtop can generate mechanical data for a wider range of parameters.”

By enabling users to directly test an additively manufactured part, and in several different locations, the PLX-Benchtop equips Renishaw with a significantly more detailed understanding of the mechanical properties of a part while streamlining the testing process. The test itself is largely automated, taking under five minutes and requiring minimal sample prep. Furthermore, by bypassing the need for coupons and associated material and machining, Renishaw is set to benefit from mechanical testing cost and time savings, a press release reads.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com