According to Shawn Allan, Vice President of Lithoz America, a Ceramic 3D printing company, ceramics are typically extremely hard to traditionally manufacture and are so delicate. This could explain the fact that research centres rely on ceramic 3D printing to produce custom scientific tools such as custom-designed crucibles and microreactors, which until now have been costly or difficult to source.

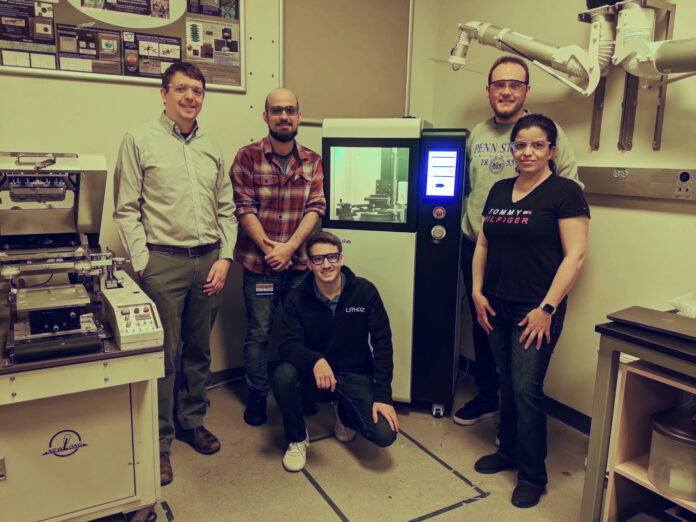

Penn State University will soon confirm the validity of this approach as its Materials Research Institute has just installed a CeraFab Lab L30.

“This will be part of a user facility here at Penn State, in the Nanofabrication Lab,” said Amira Meddeb, associate research professor in the Materials Research Institute. “The number one reason we acquired it is to allow more capabilities not just for the Penn State community but for our extended user community that we work with including other higher education institutions and industry.”

The CeraFab Lab L30, as an entry-level machine, is not only able to print a wide variety of ceramic materials that are in Lithoz’s materials library, but also can print custom materials. A condensed version of the industrial-scale CeraFab System S65 printer, the Lab retains all the power of Lithoz’s Lithography-based Ceramic Manufacturing (LCM) technology, enabling the production of very high-resolution parts and full density of ceramics that would be comparable in properties and microstructure to ceramics that are made by traditional manufacturing methods, Lithoz explains.

Material can easily be swapped out for different projects, and it is ‘relatively simple to learn how to use the printer, especially for someone with a traditional ceramics processing background’, as said by Penn State. The printer rounds out the research offerings provided by the Materials Research Institute, according to Chad Eichfeld, associate research professor and director of operations in the Nanofabrication Lab. “We can work with researchers to do the design of the material, the 3D printing of the material, but you can also do the characterization here,” Eichfeld said. “Having all of that together lets you actually do the rapid iterations of ceramic production that are necessary for our researchers’ success.”

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com