Stratasys has recently added three new 3D printers to its portfolio: the Stratasys Origin® One 3D printer, the Stratasys H350™ 3D printer, as well as the Stratasys F770™ 3D printer.

Based on different AM technologies – FDM, P3, and SAF technologies -, the new 3D printers aim to provide users with a viable alternative to move from traditional to additive manufacturing for low-to-mid-volume production applications.

Furthermore, the release of the Stratasys Origin® One 3D printer as part of this portfolio illustrates Stratasys’ ability to accelerate the go-to-market capabilities of every technology developed by its new company.

The Stratasys Origin® One 3D printer

Designed for volume production, this new 3D printer is based on the proprietary P3™ technology and a software-first architecture. It is delivered with Cloud connectivity options which means customers will receive additional feature improvements over time.

That technology combined with hardware upgrades enabled Stratasys to optimize virtually all aspects of the system in the new version of the product to improve reliability and performance.

“We have been laser-focused on meeting stringent accuracy and repeatability criteria for 3D-printed connectors that require double-digit micron accuracy,” said Mark Savage, Global Center of Excellence Leader for additive manufacturing at TE Connectivity, an expert in connectors and sensors and long-time customer of both Stratasys and Origin. “Stratasys and Origin have been great partners in helping us achieve these targets and demonstrating the possibilities of using additive manufacturing at the scale of tens of thousands of parts. Today, we’re seeing the hardware, the software, and the materials from Stratasys really come together to begin making production scale a reality for us. We believe this helps make TE Connectivity a more agile and cost-effective partner for many of the world’s leading OEMs in industries from automotive to aerospace to appliances as we work to build a more connected future.”

H350 3D Printer-based on SAF™ Technology

The Stratasys H350™ 3D printer would be the first 3D printer in Stratasys’ new H Series™ Production Platform. Powered by SAF™ technology, the H350 printer includes about a dozen different parts 3D-printed with SAF technology. Stratasys is using certified third-party materials for H Series systems. The initial material is Stratasys High Yield PA11, which is a bio-based plastic made from sustainable castor oil.

The H350 printer has been in beta testing since early 2021 with service bureaus and contract manufacturers in Europe, Israel, and the United States, including Stratasys Direct Manufacturing, which is now selling parts on demand using the system. It is expected to ship more broadly to customers in Q3 of this year. Applications include end-use parts such as covers, connectors, hinges, cable holders, electronics housings, and ducting.

“We have ambitious plans to grow our business and we believe adding a Stratasys H350 can be a key component of that growth,” said Philipp Goetz, owner of Goetz Maschinenbau, a Germany-based service bureau. “We have fulfilled orders for both large parts as well as up to several hundred smaller parts. We have been impressed with the performance of the system and SAF technology, with consistent parts throughout the build volume. The system has also been remarkably reliable.”

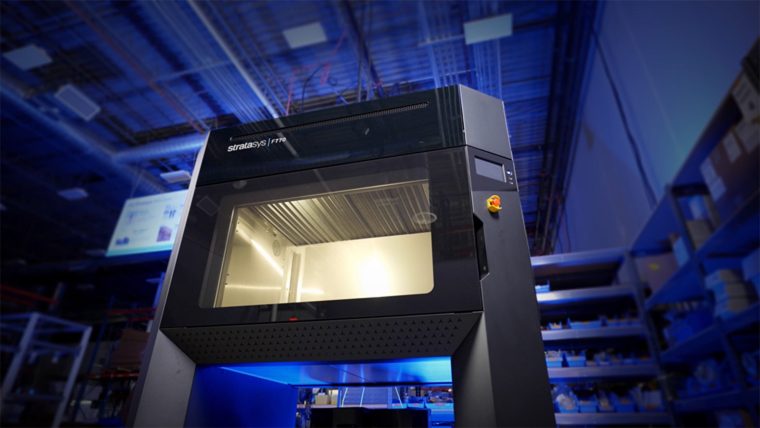

Enabling the production of big parts with F770 FDM® 3D printer

The Stratasys F770™ 3D printer, the third new system builds on the manufacturer’s reputation on industrial-grade FDM technology. Ideal for big parts, this newest FDM 3D printer features the longest fully heated build chamber on the market and a generous build volume of over 13 cubic feet.

The new system, priced under $100,000, is designed for prototyping, jigs and fixtures, and tooling applications requiring standard thermoplastics. Soluble support material simplifies post processing, while GrabCAD Print™ software streamlines workflow and enterprise connectivity is enabled through the MTConnect standard and the GrabCAD SDK.

Sub-Zero Group Inc., based in Madison, Wisc., manufactures luxury appliances, and has been a beta customer for the F770. Doug Steindl, corporate development lab supervisor, said it helps keep the printing of larger parts in-house, creating a cost savings of 30 to 40 percent. “It’s speed to market on everything,” he said. “Our 3D printing lab is faced with new product builds every six weeks. The faster we can turn things around, the better, and the quickest way we can do that is to keep as much in-house as possible. The F770 delivers on that need.”

Last year, Stratasys accrued more than 25% of its revenue from manufacturing-related applications. Going forward, with a comprehensive and integrated portfolio of 3D printing hardware, software, materials and services solutions, Stratasys estimates that its manufacturing revenue growth will outpace other segments, growing at an annual rate of over 20% starting in 2022.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com