This series of news round-up gathers the latest news on facilities’ inauguration, partnerships and M&A.

EOS is the latest AM company to adopt the CO-AM Software Platform

AM company EOS has adopted the CO-AM software platform from Materialise. The announcement follows a series of collaborations Materialise is undertaking with Sigma Additive and Phase3D.

In this specific case, CO-AM integrates with EOS’ existing infrastructure and will be used to improve the efficiency of AM production across global facilities.

EOS maintains production sites across Germany, the United States, and various locations in the APAC region. The globally distributed AM capacities serve internal demands and support EOS’ application engineering services. EOS has adopted CO-AM to manage these AM processes and enhance traceability and efficiency. The Materialise CO-AM Software Platform provides access to a full range of software tools to plan, manage, and optimize every step of the 3D printing process.

EOS integrated CO-AM into its existing infrastructure, such as data and customer relationship management software, and connected it to their fleet of equipment. CO-AM will support the EOS internal AM workflow from order management through production scheduling, build monitoring, and post-processing.

The CO-AM Scheduler for instance, shows both planned and actual printer activities to support utilization rate improvements. Within the platform, Materialise’s AMWatch software will enable operators and engineers to monitor build status and process sensor data to decrease scrap rates and improve quality control. EOS team members will also have access to data in the CO-AM platform gathered through a shop-floor iOS application. This digital feedback from the factory floor will help them to monitor unpacking, de-powdering, and post-processing activities in real-time.

Systemic Bio™ inaugurates new laboratory for Bioprinted Organ-on-a-Chip R&D, to Accelerate Drug Discovery & Development

Remember Systemic Bio™, the company created by 3D Systems to support its bioprinting activities ? They will now operate in a 15,000 sq. ft. facility in TMC Innovation Factory Labs on the Texas Medical Center Campus in Houston.

From this location, Systemic Bio’s engineers and scientists will continue the development and production of the company’s proprietary h-VIOS™ (human vascularized integrated organ systems) organ-on-a-chip platform. The laboratory integrates a cleanroom manufacturing intended to support sterile production of thousands of h-VIOS chips and plates.

h-VIOS is a versatile organ-on-a-chip platform that can recapitulate several organ and disease functions. Composed of vascularized hydrogel scaffolds, the h-VIOS platform enables the survival and function of human cells, both healthy and diseased, as well as the delivery of drugs to these cells in a more physiological manner. The establishment and further validation of these systems has the potential to significantly reduce both the high costs and extended times required for pharmaceutical companies to bring new drugs to market. The new center of excellence for scaffold manufacturing will enable sterile and quality-controlled production of h-VIOS chips and plates to be used by Systemic Bio’s pharmaceutical partners in drug testing. To oversee manufacturing operations, Systemic Bio hired Jeremy Carter as its Vice President of Operations. Jeremy has more than ten years of experience with GMP and FDA-regulated biopharmaceutical production at leading biotech companies such as Grail and Thermo Fisher Scientific.

AddUp opens news AM facility in Germany

OEM AddUp has established a new Tooling Competence Centre in Aachen, Germany. The announcement is no surprise given the company’s recent activities in the region. As a matter of fact, the Tooling Competence Centre is located within the WBA Tooling Academy in Aachen, Germany.

In addition to this additive manufacturing facility, a new office in Aachen will serve as AddUp’s German subsidiary (AddUp GmbH) and host a local team of AM engineers ready to support companies to industrialize AM.

As a reminder, AddUp has extensive experience in the tooling industry developing applications and materials best suited for mold and tool production. The Tooling Competence Centre provides a resource for tooling manufacturers to validate their applications and partner with an expert in PBF technology. The facility is equipped with a FormUp 350 PBF machine and tool makers will have the opportunity to submit application cases for evaluation beyond a simple proof-of-concept. They will be able to study all aspects of their project, from the design applied to PBF, to the profitability analysis and the study of series production.

This is the group’s second AM facility outside of France, following the opening of a new Solution Centre in North America last year.

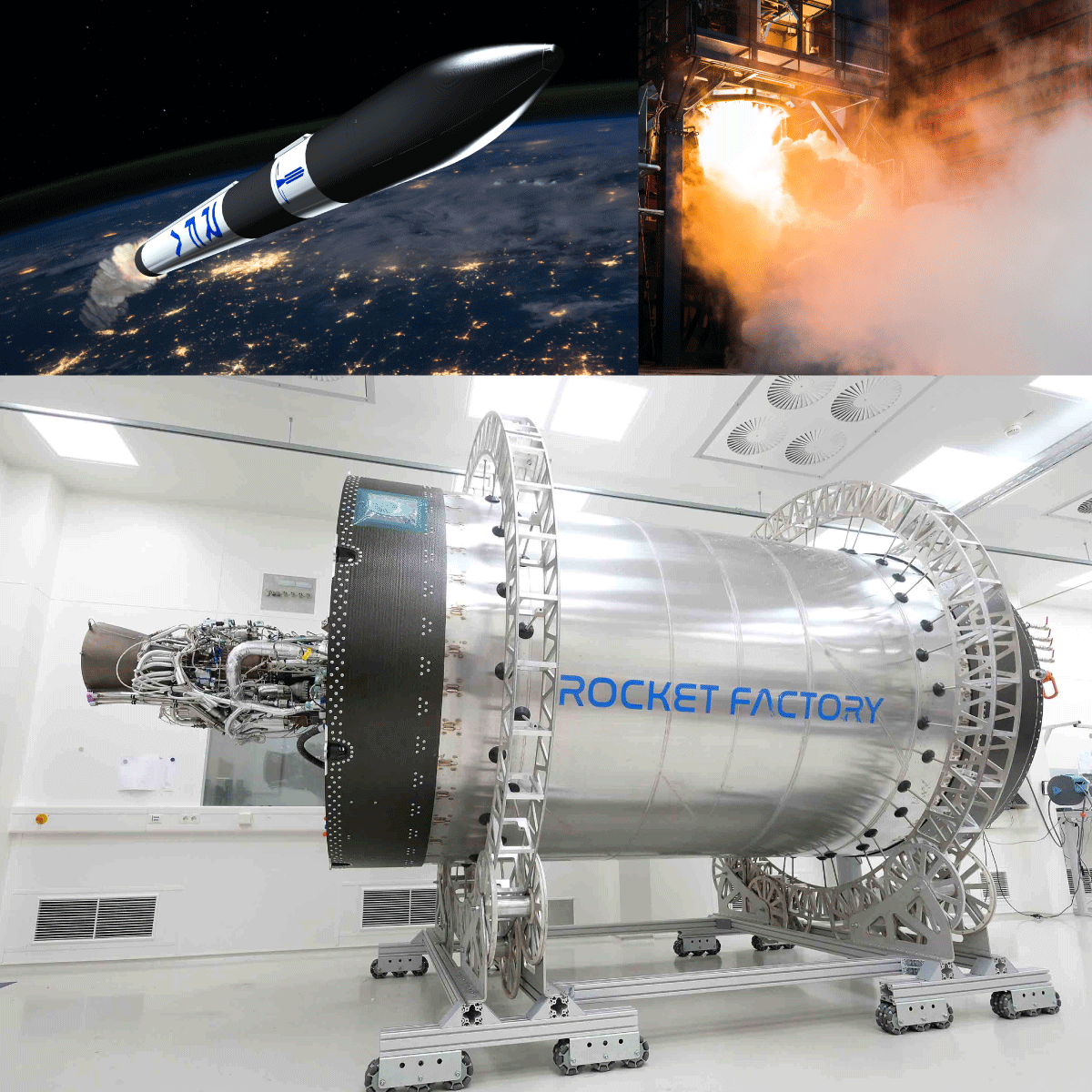

Conflux Technology and Rocket Factory to develop aerospace heat exchangers

Conflux Technology, the developer of metal 3D printed heat exchangers, will be involved in Australian Space Agency’s Moon to Mars Initiative : Supply Chain Capability Improvement Grant Program.

As seen with other countries, the initiative supports Australian organisations with projects that could contribute to NASA’s endeavour to go to the Moon and on to Mars. This initiative is also an important element of the Agency’s goal to transform and grow the Australian space industry.

In this vein, Conflux signed a partnership with Germany-based Rocket Factory Augsburg (RFA) where it will embed its heat exchanger into a gas duct of an orbital rocket. The partnership includes then the Materials qualification and testing of Monel 500K, using the production platform – EOS M300-4 as well as the development, build and functional text of the gas duct heat exchanger by the end of this year.

Stratasys finally completes acquisition of Covestro

Talks have been going on since last year but now the deal is sealed: Stratasys has completed the acquisition of the additive manufacturing materials business of Covestro AG.

The acquisition, which is immediately accretive, includes R&D facilities and activities, global development and sales teams across Europe, the U.S. and Asia, a portfolio of approximately 60 additive manufacturing materials, and an extensive IP portfolio comprised of hundreds of patents and patents pending.

From a manufacturing standpoint, this means that Covestro’s materials, IP portfolio, and talents will help Stratasys address new applications in key technology categories such as stereolithography, P3/DLP, and powder bed fusion, including SAF™ technology. They will also complement Stratasys’ materials expertise for PolyJet and FDM® technologies.

All materials are available through Stratasys and its global partners under the Somos® and Addigy® brands, benefiting customers with greater global sales, service and support infrastructure. Stratasys will continue to fully support customers whether the materials are used with Stratasys or third-party 3D printers.

“A new material can be as transformative to a market as a new 3D printer,” Hugo da Silva said. “Whether it’s flame, heat and smoke resistant materials for aerospace, new biocompatible materials for medical applications, or resilient materials with ESD properties for electric vehicles, we know that the more we bring new materials innovations to market as part of use case solutions, the more we can transform how everything is manufactured around the world.”

da Silva was previously Vice President of Covestro Additive Manufacturing. He will now serve as Vice President of Strategy, M&A and Venturing at Stratasys.

iSpecc Limited Now Handling Thermwood Sales, Service and Support for the UK

U.S.-based, multinational, diversified machinery manufacturer Thermwood has announced that iSpecc Limited, located in Shrewsbury, UK, is now the exclusive dealer, service and support representative in the UK for its products. The latter include the company’s line of 3- and 5-axis CNC routers and LSAM large scale additive manufacturing systems.

As a reminder, Thermwood is among the top companies in the field of large scale additive manufacturing of thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These machines can be used by companies across aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com