Enabling industrials to reimagine additive tooling has always been the vision of OEM 3D printer manufacturer AddiFab. Delivering productivity and safety benefits through ultrafast polymer 3D printing has been the leitmotiv of 3D printer manufacturer Nexa3D. Both machine suppliers are joining forces today to bring production of moulds to unseen levels.

They develop a novel 3D printed injection mold tooling platform where injection moulders across the world will get to use an NXE 400 3D printer with the freeform injection moulding (FIM) platform.

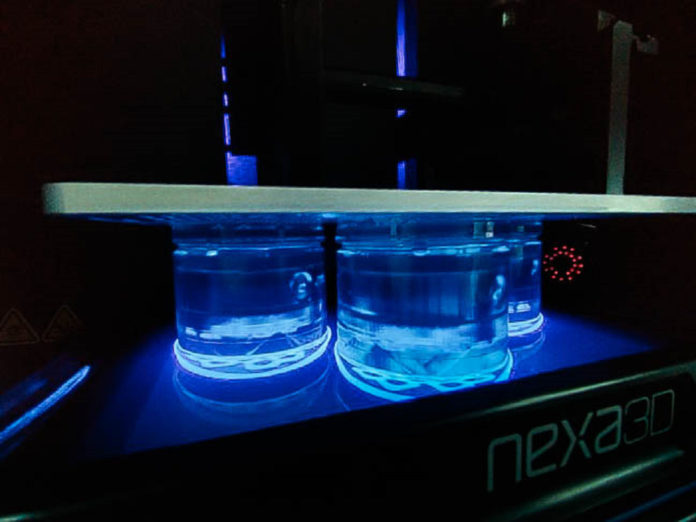

As a reminder, Nexa3D’s NXE 400 3D printer is an industrial photopolymer resin 3D printer that features 2.5x build volume as well as ultrafast 6.5x speed. The machine leverages Nexa3D’s proprietary LSPc patented technology and can print up to 16 liters of parts volume 275 x 155 x 400mm (10.8″ x 6.3″ x 15.7″) at speeds of up to 10mm (3/8″) per minute.

AddiFab’s FIM process on the other hand delivers the freedom of additive manufacturing with the volumes of injection molding in a unique manufacturing process. Based on 3D printing technology, the FIM process allows the user to additively manufacture complex injection mold tooling in hours instead of weeks or months. These tools are compatible with most thermoplastic materials, including reinforced high-performance feedstocks. They can also be dissolved, which allows the molding of complex components that would otherwise be difficult – or even impossible – to mold with conventional metal tooling, a press release reports.

Combining both capabilities will therefore enable manufacturers to benefit from speed and volume production: a dream production in AM. As from now, Nexa3D will supply their NXE 400 system – including the industrial 3D printer as well as wash and cure units – to users of Freeform Injection Molding, while Addifab will be supplying their proprietary tooling resins and post-processing equipment.

“With Freeform Injection Molding, we provide injection molders with a fully transparent set of tools (no pun intended) that will allow them to fast-track tool designs and validations while raising the bar on tool innovation. Now we can take these capabilities to the next level by partnering with Nexa3D to broaden access and superpower performance”, Lasse Staal, co-founding CEO of Addifab comments.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com