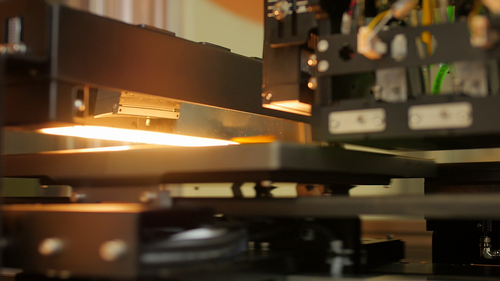

Israel-based specialist of 3D Printed electronics has launched a new printing technology this morning. Called LDM for Lights-Out Digital Manufacturing, the technology is integrated into a system that runs with little human intervention.

For DragonFly users in the additive manufacturing industry, LDM means a faster printing of electronic circuitry and a wide range of opportunities for short-run, small volume manufacturing of printed electronics.

Nano Dimension targets Industry 4.0 and the Internet of Things

The provider of 3D printed electronics targets new industries with the new system. As an extension of the well-known DragonFly Pro, the LDM system combines new advanced printer head software management algorithms with an automatic self-cleaning of its print heads every few hours. The new system is equipped with real-time automatic material monitoring capabilities that ensure maximized runtime.

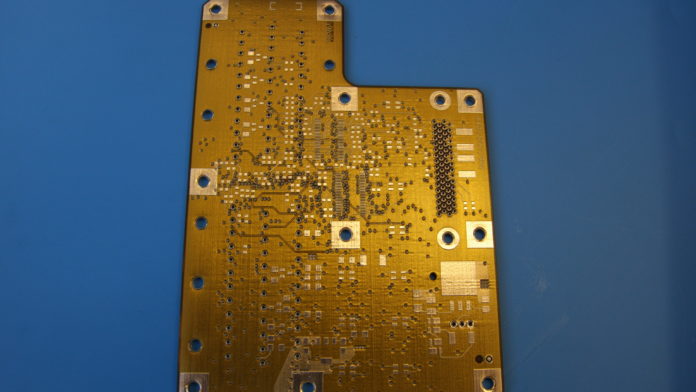

Applications remain the same: PCBs, capacitors, coils, sensors, antennas and more.

“The DragonFly LDM is designed to help our customers prepare for Industry 4.0. and stay competitive in a world that demands electronic devices with increasingly sophisticated features. Like its predecessor, the DragonFly Pro, it’s the first of its kind on the market, carefully designed for both ease-of-use and even more agile, faster and affordable 3D printing of functional circuitry. “We’re confident that the LDM system will provide best in class additive manufacturing,” said Amit Dror, CEO and co-founder of Nano Dimension.

First experience

For HENSOLDT, the existing working experience in realizing 3D printed multilayer circuits with the multi-material inkjet-process, offered by Nano Dimension, shows that a high amount of personal care is needed to keep the printer system operational. The implementation of the new LDM system allows for a significant reduction of time and cost for realizing circuits, which are often needed as fast as possible.

During the joint LDM-campaign, HENSOLDT contributed by generating reference circuits to outline the advantages of the new LDM system.

The comparison of the actual printing time showed that the LDM system achieves more than40% higher printing time.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

https://pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});