Dyndrite recently held its “Dyndrite Day”, a two-hour event that enabled the US-based software company to reveal more about its products, applications and strategic partnerships.

Main guests at the event were Anthony Graves from HP, and Greg Morris from Vertex Manufacturing.

Anthony Graves’ presence at Dyndrite Day coincided with the 3D printer manufacturer’s announcement on “HP Universal Build Manager”. As a matter of fact, the conversation between Graves and Harshil Goel, CEO and founder, Dyndrite gave an interesting background on their first meeting at Formnext 2019, how the partnership between HP & Dyndrite effectively started and how it was deepened.

As a reminder, Dyndrite debuted on the international scene last year in Frankfurt. Amid the array of additive manufacturing professionals, Goel demonstrated the potential of his company’s Additive Manufacturing Toolkit (AMT), CAD-to-print workflow software through a very accurate presentation. It was also the opportunity to highlight the importance of their Developer Council: a central component of the company’s program that aims to evolve the Dyndrite platform, industry standards, and create seamless customer experiences by cross-leveraging tools that elevate the industry as a whole.

At 3D ADEPT Media, we recently discovered a part of the company’s vision in the latest issue of 3D ADEPT Mag. In that issue, Goel and Ty Pollak from Open Additive, shared the key reasons why they believe open systems and advanced software are the future for the industry.

So, where is Dyndrite headed?

To date, Dyndrite has added three new members to its Developer Council Program, AddUp, EnvisionTEC, and Link3D, which brings the total of its members to 20.

The software specialist also develops a new ToolPathing API for enabling standards across the industry. With the goal of creating and handling massive data-rich voxel sets with eyebrow-raising performance, the new API finds its place in scientific and engineering workflows.

According to Goel, “this is the first voxel manipulation tool hypertuned for the accuracy and resolution needed in modern scientific and engineering workflows, including digital manufacturing. With the increasing sophistication of CT scanners, MRIs, and additive manufacturing print heads, developers require more powerful tools to realize the full capabilities and resolution of their hardware. We look forward to working with our partners and customers to put this power into the hands of their end-users.”

The Seattle-based organization may have emerged from stealth mode recently but has made it clear they wanted to target performance with the development of their geometry kernel. The Voxel API tool is a key milestone in the achievement of this objective since it improves the Dyndrite geometry engine.

“Voxels are the language for a growing number of high-speed additive manufacturing processes and devices – especially those aimed at production,” said Gareth Neal, Customer Applications Manager & 3D Specialist at Xaar PLC. “We need ways and methods to quickly create, enrich and prepare data for output. The Dyndrite Voxel API is a standout solution that could provide those outcomes.”

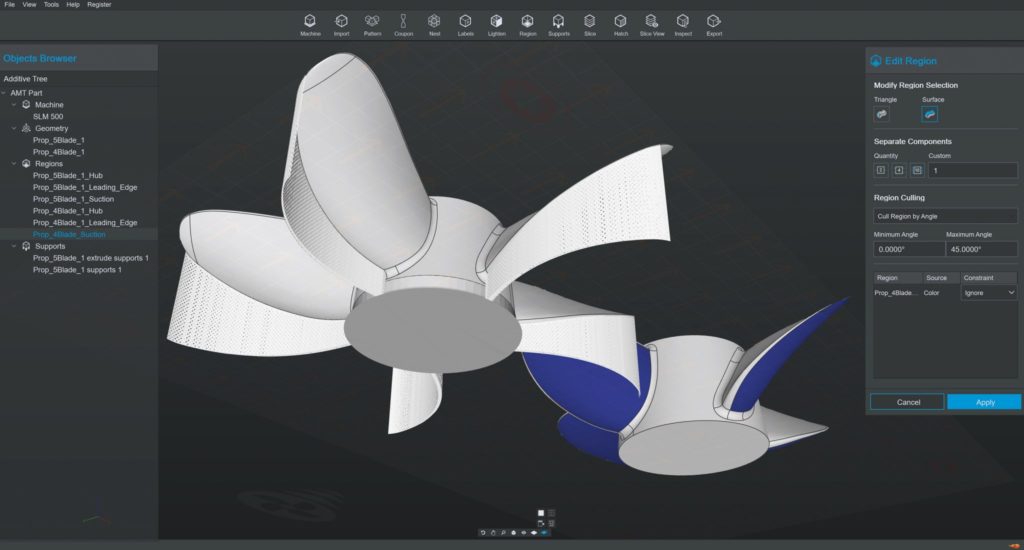

Next to the API tool, we’ve learned about the new HP Universal Build Manager. As its name indicates, this AM manager is universal and utilizes both HP’s proprietary software and data innovation and Dyndrite’s Accelerated Geometry Engine.

According to both companies, the Universal Build Manager is based on the GPU-accelerated processing and Python scriptability inherent to Dyndrite’s engine. When combined, the capabilities of these tools simplify and automate build preparation across their additive manufacturing technologies at supercharged speeds.

Keep in mind that this time, this is not just about HP’s Multi-Jet Fusion as the manufacturer wants to enable multi-platform additive workflows across various machine fleets such as Binder Jetting (BJT), Laser Powder Bed Fusion (LPBF), Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), Selective Heat Sintering (SHS), Electron Beam Melting (EBM), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), High Speed Extrusion (HSE), Stereolithography (SLA), Digital Light Projector (DLP), Laminated Object Manufacturing (LOM) and Composite-based Additive Manufacturing (CBAM).

“We are addressing software challenges in the additive industry that have prevented it from becoming mainstream and are providing capabilities to help customers accelerate the journey to digital manufacturing,” said Ryan Palmer, Global Head of Software, Data and Automation, HP Personalization & Industrial Business. “The new HP Universal Build Manager simplifies, automates, and delivers a digital-first approach to manufacturing. This solution will enable customers to explore new areas of complexity and value, push the boundaries of sustainable production, and automate critical steps in their digital workflow.”

The new solution has already been put in practice at Cobra Aero and Cobra Moto, two companies that need their technology to work at its best, as they design and manufacture propulsion systems for high-intensity applications including racing, fire fighting, and aerospace.

While waiting for Cobra’s testimony on the solution, we can already point out its main features:

- Universal support for the most widely adopted additive processes

- Support for industry standard CAD and vendor-neutral formats enabling CAD-to-print workflows for all major MCAD applications

- High-performance GPU-accelerated geometry engine helping accelerate computational tasks such as support generation, slicing and tool pathing

- Highly scalable architecture designed to support high-part density builds to optimize throughput and minimize cost

- Powerful Python-based automation engine to capture expert knowledge, process definitions and the ability to streamline workflows and automate repetitive tasks in support of lights-out digital factory solutions

- Extensible plug-in framework making the versatility and power of the HP Universal Build Manager platform accessible to every user, machine manufacturer, and software vendor, facilitating the creation of process specific solutions without having to share potentially sensitive IP.

It’s been a while that we keep discussing process support, forgetting sometimes that support and integration from machines vendors are necessary. The release of this Universal Build Manager and its capabilities just makes things more interesting.

Remember, you can post AM job opportunities for free on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com