The ALTRA 280 will debut in North America at the RAPID+TCT show in Los Angeles (Booth 839), California, on June 25, 2024, and will be available across the region starting July 2024. It is the first solution BigRep developed in collaboration with HAGE3D, a company whose acquisition has recently been announced.

BigRep has added a high-temperature 3D printer to its portfolio. The German OEM known for its large-scale Fused Filament Fabrication (FFF) 3D printers aims to meet the production requirements of demanding applications.

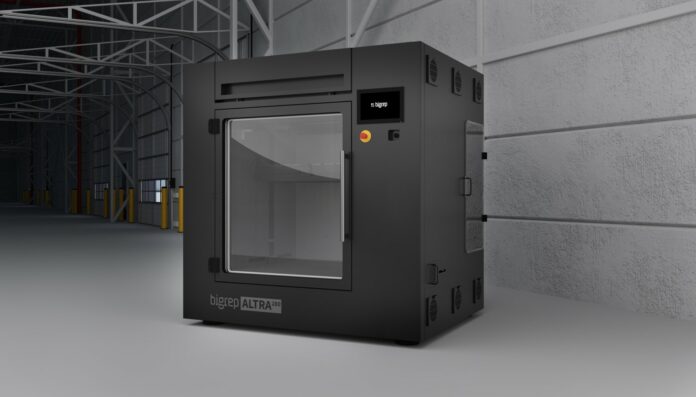

Named the ALTRA 280, the new 3D printer is powered by FFF technology and features a fully enclosed high-temperature printing environment, an open material system compatible with BigRep and third-party filaments, and a massive build volume.

The highlights of the ALTRA 280 are the heated 500 mm x 700 mm x 800mm build chamber capable of reaching temperatures as high as 180°C, up to four state-of-the-art DSX extruders for uninterrupted production, and the fully automated quick start feature for 3D printing at the touch of a button.

According to Dr.-Ing. Sven Thate, Managing Director of BigRep GmbH, the company aims to double the addressable market of its solutions with the technology from HAGE3D, its recently announced planned acquisition.

“Backed by our 3D printing ecosystem of an intuitive software suite, global customer service, and an eLearning platform, we have customer’s success in focus as we expand our offering to high-performance applications,” he adds.

Key features of the ALTRA 280 include:

- Large-Scale 3D Printing: A generous build volume of 500 mm x 700 mm x 800mm (volume of 280 liters) designed to produce intricate fully-fledged prototypes, production-, and end-use parts.

- High-Temperature Capabilities: Prints with high-performance materials such as PEI 9085 and PC.

- Uninterrupted Productivity: Equipped with up to four DSX extruders, the ALTRA 280 delivers seamless production with dual extruders and two respective backup extruders, enabling reliable performance around the clock.

- Fully Automated Quick Start: The ALTRA 280 is designed for easy operation, with fully automated calibration and pre-heating processes.

- Heated Vacuum Print Bed: engineered for secure adhesion of the part and superior layer adhesion, even for large intricate prints.

Thomas Janics, Managing Director of HAGE3D GmbH said, “We believe that the ALTRA 280 will transform the way manufacturers approach additive manufacturing, especially in the aerospace, military, and automotive segments, where high-performance parts are crucial.”

Remember, you can post your job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com