Mantle officially debuts on the additive manufacturing industry with a proprietary 3D printing technology named TrueShape. This entrance on the AM industry follows an unannounced $13M investment by Foundation Capital, Hypertherm Ventures, Future Shape, 11.2 capital, Plug and Play Ventures, and Corazon Capital.

The US-based manufacturer claims to achieve high-precision metal parts while improving the time-consuming and expensive process of creating tools. Its solution? A unique metal 3D printing technology designed for the tooling market.

Historically, product development cycles have been gated by tooling since manufacturing companies cannot launch new products until the exact molds and dies to produce them are created. These tools are made from high-hardness steel through a multi-step process that includes programming, cutting, and finishing the tools. This intensive process takes months and can cost tens to hundreds of thousands of dollars. Mantle’s process takes just days, which allows companies to deploy new tools within a few weeks while cutting costs by at least half. The result is that companies can innovate with new products faster than ever before.

“Manufacturers require proven part quality and performance. By using Mantle printed tooling, they can continue to use the same high-performance thermoplastics and get parts of equivalent or superior quality in less time and at a lower cost,” said Ted Sorom, CEO and co-founder of Mantle. “We help companies speed their products to market with dramatically faster new product introductions while leveraging their proven mass production expertise.”

The 3D printing industry has pursued the tooling market for over 20 years. However, until Mantle, other 3D printing technologies have been too imprecise or too expensive to be successful. In the tooling industry, precision matters: a tool that is too big or too small by ½ the width of a human hair can be the difference between a product that works and one that does not. Mantle’s TrueShape™ process is the first 3D printing technology that meets these requirements because it:

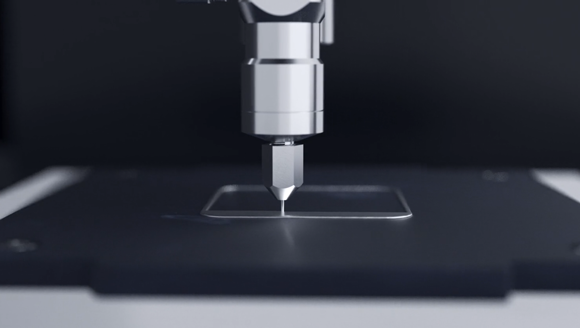

- Combines both additive manufacturing and subtractive finishing into a single hybrid 3D printing process to yield superior accuracy and surface finish

- Uses unique metal pastes that produce high-hardness steels that meet or exceed the tooling industry’s demanding requirements

Using a 3D printed Mantle tool insert, a global appliance manufacturer has already produced over 200,000 washing machine parts. The Mantle mold component cost 67% less than the cost from traditional methods and was produced in 70% less time. Similarly, a leading medical device manufacturer reduced the lead time for its tool by 80% with Mantle. The printed tool performed just as well as tools made with traditional methods.

“Mantle is taking on the overlooked $45 billion tooling market that is a bottleneck for innovation because it is a slow process that has not changed significantly in 70 years,” said Steve Vassallo, General Partner at Foundation Capital. “Until Mantle, no one has been able to develop tooling tech that is disruptive in either time or cost, let alone both, which made backing Mantle an easy decision for us.”

Mantle’s TrueShape™ technology includes multiple tool steel materials, custom printing hardware, and a user-friendly software suite to deliver toolmakers a complete production-grade tooling solution. Tooling is just the beginning for Mantle. Additional solutions are on the roadmap for a wide range of applications in the $300B precision parts market, including jigs and fixtures, low volume industrial machinery and spare parts, and high volume part production.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com