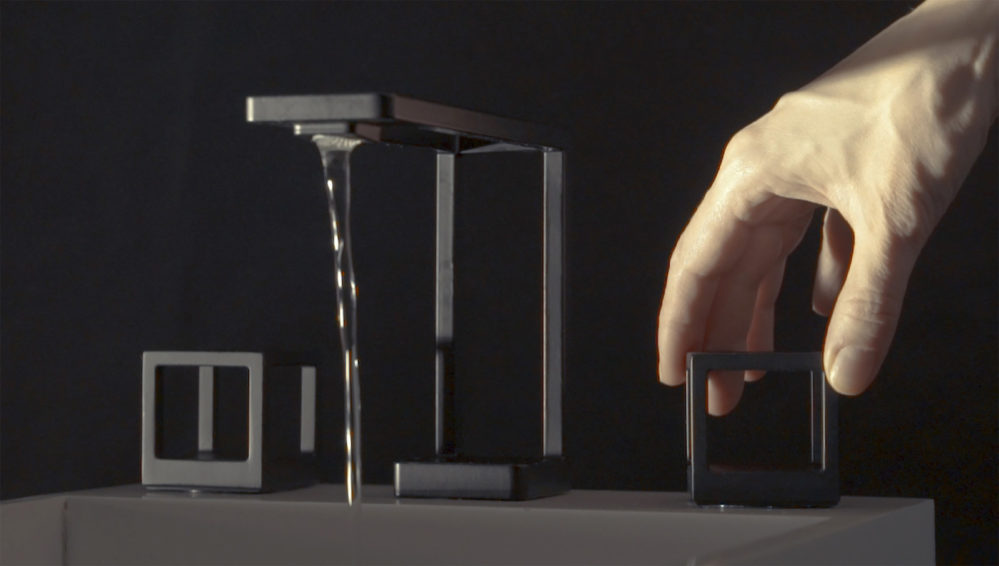

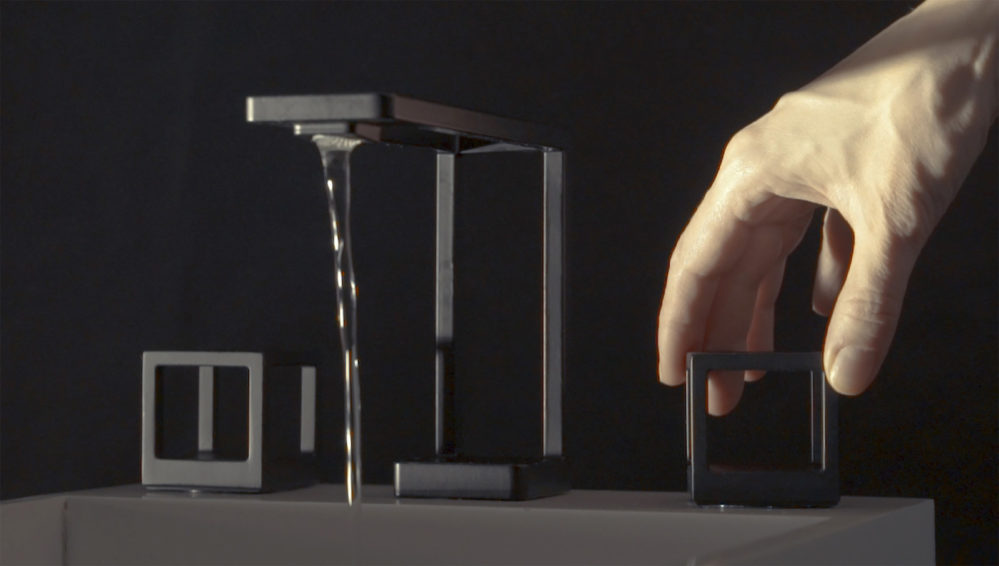

KALLISTA, a designer and provider of luxury kitchen and bath products, released yesterday at KBIS 2018 a Grid™ sink faucet, first of its kind on the market – produced by 3rd Dimension using 3D Systems’ 3D printing materials and technology -. It is the first time, KALLISTA used 3D printing to manufacture a product, a positive experience which enabled the designer to save time and “produce the Grid faucet flawlessly.”

3rd Dimension is a metal manufacturer specializing in 3D direct metal printing based in Indianapolis.

3D Systems’ Direct Metal Printing Solution changes the rules of Design and Production for KALLISTA

KALLISTA’s design team wanted to create a faucet in a unique geometry. By using 3D printing, the designers were able to design without limitations to create an open form and discreet interior channels that allow water to flow easily through the base.

Bill McKeone, design studio manager, KALLISTA explained that designers usually have to use a manufacturing process and have to design around that process. “By choosing to produce this faucet via 3D printing, we opened ourselves to limitless design possibilities. 3D Systems’ breadth of materials and technologies allowed us the freedom to create a unique, functional faucet which would not have been possible with a traditional manufacturing process.”

As for 3rd Dimension, it used 3D Systems’ ProX®DMP 320 metal additive manufacturing system, and LaserForm® 316L, a stainless steel 316 powder material which enables them to avoid rust and corrosion.

“This is just one example of the value 3D printing brings to a production environment,” said David Cullen, director of applications engineering, 3D Systems. “Through the combination of materials, print technology, software and services, KALLISTA was able to bring their visionary design to market.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});