Incus, the company behind lithography-based metal manufacturing (LMM) has announced the progression of 99,9% pure copper material to the production stage. The Austrian company first collaborated with collaborated on copper development, and is now debuting its internal R&D activities.

“We’ve been working on the most important aspect for copper-printing, the LMM binder system, for about a year. With the first furnace runs, we have achieved an impressive, isotropic 92% of the electrical and thermal conductivity of conventionally produced copper. The total time in the sintering furnace was optimized to below 12 hours,” the company explains.

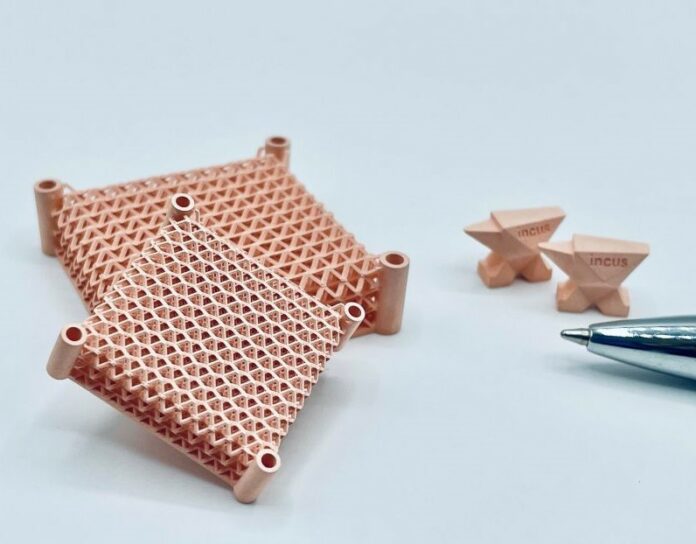

The announcement follows a series of improvements of its LMM technology – defined as a vat photopolymerization process (VPP) by ISO/ASTM –. With the LMM process, it is possible to 3D print intricate copper parts with great surface aesthetics and complex geometries.

One of the key strengths of LMM is its ability to eliminate support structures for the printing process and ensure a homogeneous powder distribution free of any defects, ensuring the best possible material performance.

“The Incus technology is unique for its high solid loading of up to 60Vol% of copper powder, enabling the highest density and optimal shape post-sintering. It is commonly known in the world of sinter-based technologies that high solid loading is key to achieve the best mechanical properties and to prevent deformation during sintering. The reason to be able to reach such high solid loadings in LMM lies in the combination of the binder system and the unique recoating mechanism developed by Incus. Part homogeneity and quality remain consistent, irrespective of part volume, allowing us to print both smaller complex parts and larger volume parts simultaneously with one parameter set,” the company adds.

According to the company, there are various applications of oxygen-free copper, for instance, thermal management systems, electrical connectors, and RF communication – applications that we hope to discover soon.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com