We were keen to discover what would be the first application that would result from Headmade Materials and Element 22’ collaboration. The answer is: 3D printed titanium parts for Sturdy Cycles’ bikes.

As a reminder, Headmade Materials develops a sinter-based 3D printing technology that can print metal parts. It is called Cold Metal Fusion (CMF). Element 22 is a developer and manufacturer of Titanium parts using various powder metallurgy technologies. It recently installed a Formiga P110 SLS system from EOS. The machine is currently being used with Headmade’s Cold Metal Fusion technology for industrial Titanium 3D printing.

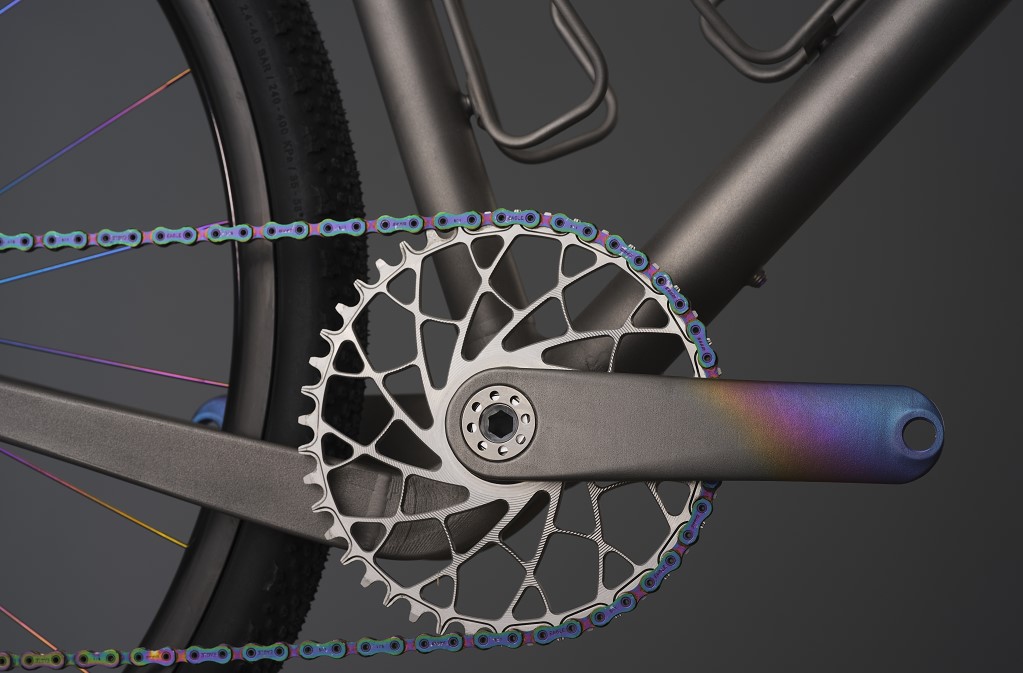

On the other hand, if you read us every day, you will realize that it is not the first time you heard about Sturdy Cycles. No later than last week, we reported on the company’s launch of 3D printed Titanium Crankset. What a pleasant surprise then, to discover the companies behind this production!

Behind Sturdy Cycles, stands Tom Sturdy, an England-based technology-loving frame builder. When he designed the Fiadh model bike, a sporty road bike designed for high speed, he knew AM would be part of the production and the manufacturing process made him recognize the potential of Cold Metal Fusion technology (CMF) for his custom bicycles.

Indeed, the Fiadh is very light and responsive, thanks in no small part to the weight-optimized titanium components made with CMF technology. Incidentally, Fiadh (pronounced fee-ah) means “wild” or “free,” which also fits perfectly with the design possibilities of an additive design.

Headmade explains that the frameset consists of connectors additively manufactured with CMF technology, which are welded to polished tubes. These connectors accommodate all major bike components, such as the handlebars, saddle and bottom bracket. The chainstay is even made entirely of components additively manufactured with CMF technology. Also, the crank arms, that we saw the first time we talked about Sturdy Cycles is made with CMF. Remember, it is now being delivers as a standalone part by Sturdy.

The individual segments of each bike are very similar in structure and design, but no two are alike. Through a concept of connecting parts tailored to the rider, all components are different in their dimensions, which has become economically feasible in high volumes with CMF technology. Of the Fiadh, Sturdy Cycles aims to produce annual quantities in the triple digits, the company continues.

We were already aware of the advantages of CMF for bike components. As a reminder, we first discovered Headmade through a novel metal 3D Printed bike pedal. These advantages include process stability and repeatability which results in this case, in easier and more efficient frame and part production.

Furthermore, there is less stress in the metal parts compared to SLM parts. The improved part surface greatly simplifies surface finishing, as CMF technology does not require support structures to be mechanically removed from the part.

For Sturdy, the reduced amount of preparatory work compared with SLM components means a significant gain in efficiency, as components can be integrated into the bike manufacturing process much more quickly. In addition, better component quality means that most of the work can be done on site at Tom Sturdy’s production facility, reducing costs and coordination with service providers.

“The production of the components has now been completely taken over by titanium specialist Element22 and we are happy to contribute with our Cold Metal Fusion technology to ensure that these dreamlike road bikes from Sturdy Cycles find their way to many satisfied customers” says Managing Director Christian Fischer, Headmade Materials.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com