Remember when I told you there are two types of people working with 3D printed parts: those who know how to deal with support structures and those who don’t?

Well, for those who don’t, OEMs continue to develop solutions that will help to produce parts without any support. One solution recently developed in this regard is the SRS Technology – Support Reduction System from OEM Farsoon.

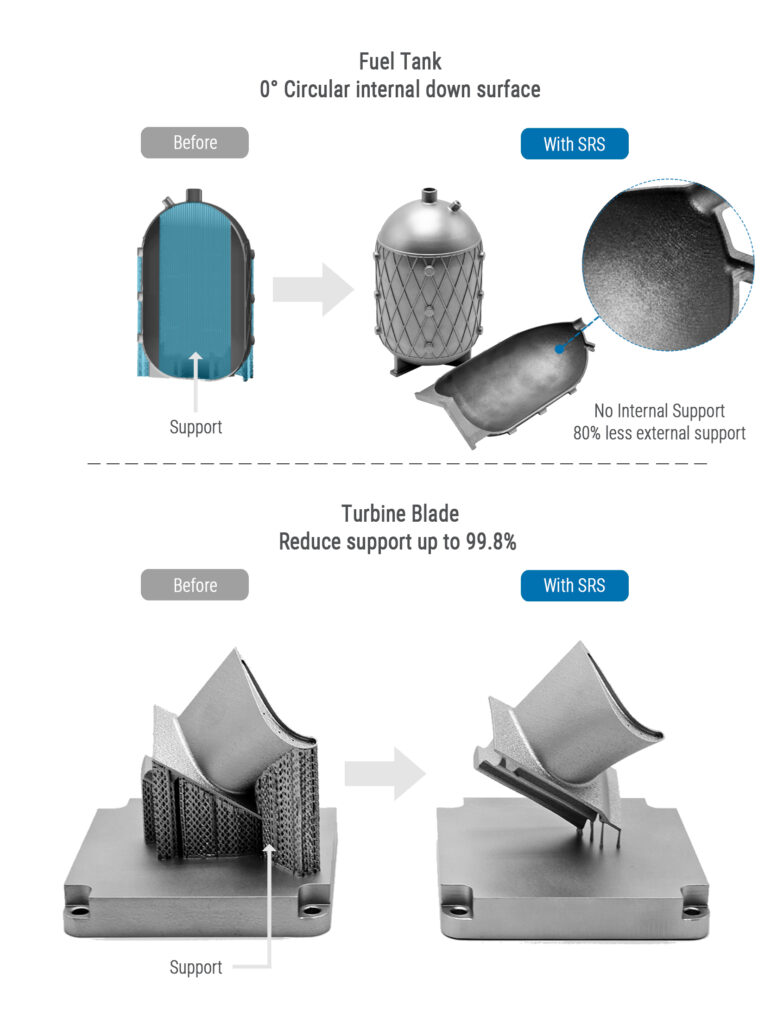

Designed for metal powder bed fusion, this solution would allow fewer supports compared to the standard metal PBF process. It enables the fabrication of inverted conical structures and horizontal circular holes with no support.

The SRS innovation addresses one of the most challenging aspects of additive manufacturing—internal stress and deformation during the cooling phase of metal powder bed fusion, which can lead to part failure, especially in overhanging structures. Applicable to all Farsoon metal PBF platforms, the new SRS technology successfully forms inverted conical structures with a 20°-25° angle and support-free horizontal circular holes up to 50mm in diameter (See figure 1), the company explains.

To highlight an example of this solution’s capabilities, Farsoon explains that a closed impeller made of IN718 material, approximately 130mm in diameter and 50mm in height, can now be printed 33% faster, with cost reductions exceeding 25%.

To highlight an example of this solution’s capabilities, Farsoon explains that a closed impeller made of IN718 material, approximately 130mm in diameter and 50mm in height, can now be printed 33% faster, with cost reductions exceeding 25%.

The SRS technology would be compatible with the company’s proprietary slicing software and adaptive intelligent scanning solutions which allow for precise control of energy input and local part temperature. This ensures high part density and significantly improves the capability of forming low-angle structures over traditional scanning technologies.

The manufacturer has applied this minimal support technology to a variety of real-world materials and applications, including titanium alloys, high-temperature alloys, aluminum alloys, and stainless steel.

The manufacturer has applied this minimal support technology to a variety of real-world materials and applications, including titanium alloys, high-temperature alloys, aluminum alloys, and stainless steel.

Farsoon’s SRS would help save material costs and reduce printing and post-processing time while minimizing potential damage to the part. Its ability to mitigate the risk of part failure makes it ideal for AM applications across demanding industries such as aerospace and automotive. Applications range from combustion chambers to closed impellers, valve bodies, and nozzles, with the largest parts exceeding 450mm.

Read more: The quest to avoid or minimize support structures In Additive Manufacturing (pp 21-23).

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com