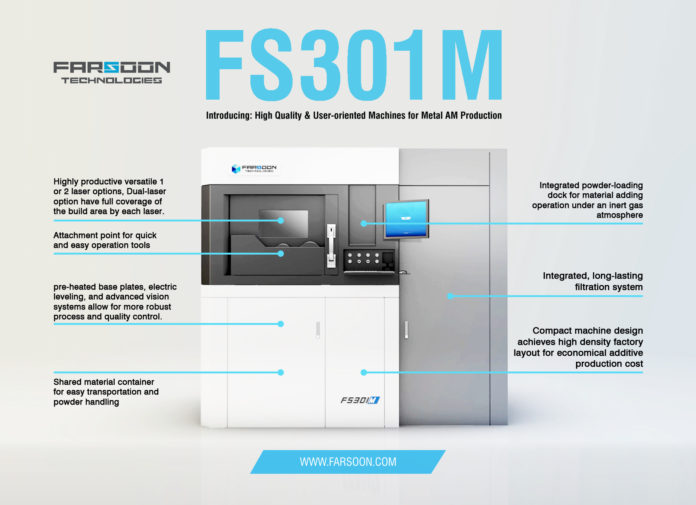

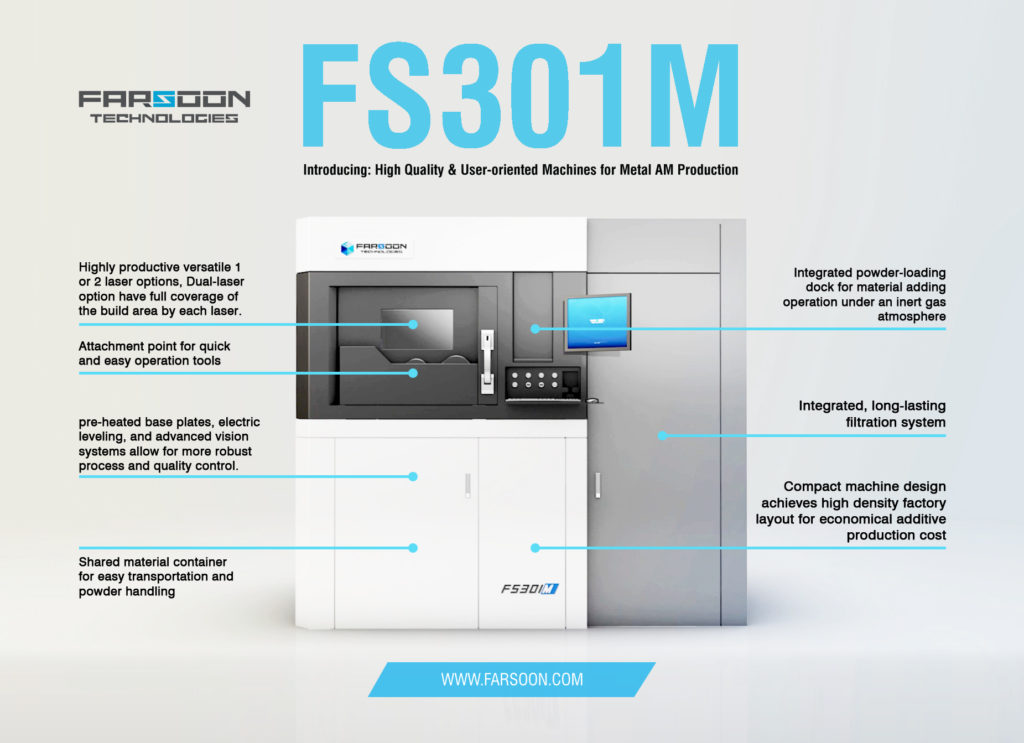

Farsoon has recently installed the new FS301M metal powder bed system at an end use aviation customer in the U.S.

The system is a dual laser industrial 3D printer designed to meet the stringent requirements of the aerospace industry. Indeed, it delivers high productivity thanks to its dual-laser scanning features and calibration algorithms, its flexibility and its enhanced user operation; not to mention that with the compact machine design, the system presents a machine footprint as small as 3.64 square meters and integrates a long-lasting filtration system with operation time up to 1500 hours. Furthermore, with operational access from only the front and rear, the FS301M enables optimization of space during the installation in a factory. With the ability to achieve high density layouts with minimal side distance, Farsoon explains the FS301M achieves maximum throughput yield per floor area at an economical additive production cost.

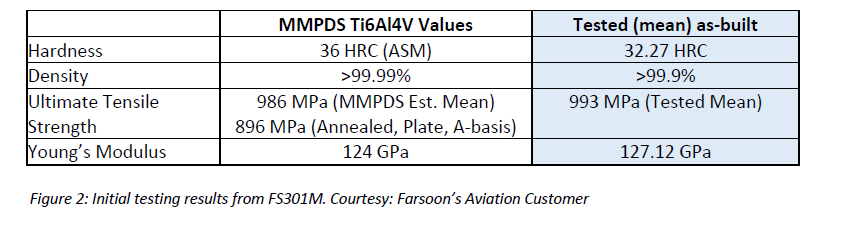

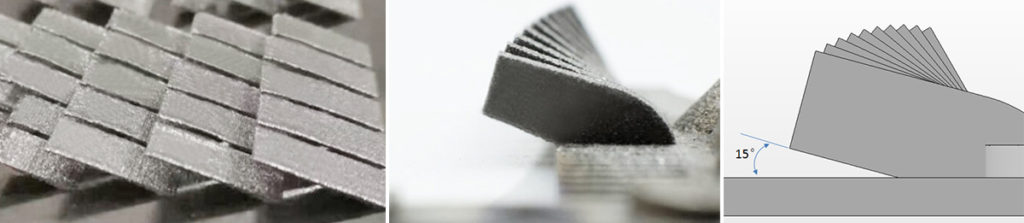

According to the manufacturer, the initial qualification and testing data from the joint process development demonstrates excellent capabilities for additive and near-wrought properties.

“The material data we’re seeing on the 301 is at the top tier in the industry,” The FS301M aviation customer stated after reviewing the testing result, “With surface roughness below 5um Ra, static performance at or above wrought, and fatigue performance within the order of magnitude of wrought with as-built surface, the 301 finally allows for economical production without compromising part quality.“

Speaking of materials, it should be noted that Farsoon open systems give customers a wide range of choice when it comes to materials. In this vein, a recent collaboration with Lubrizol gives now Farsoon customers the ability to explore AM applications with TPU-powders.

Lubrizol’s TPU-powders and their use on Farsoon laser sintering machines

Lubrizol Engineered Polymers brings more than six decades of experience in the formulation of engineered polymers. The company’s activities in the additive manufacturing industry led to partnerships with 3D Printer manufacturers such as Ultimaker.

As part of this partnership with Farsoon, Lubrizol has developed TPU-powders that can be processed on Farsoon laser sintering machines. Following the successful test performed by both companies, customers will now be able to perfectly leverage the material-machine combination.

Dr. Dirk Simon, Managing Director of FARSOON Europe GmbH: “Lubrizol is a strong player in TPU materials and instrumental in industrial applications, classically and in 3D printing. We appreciate that Lubrizol jointly with Farsoon push for the industrialization of additive manufacturing. For instance, the Lubrizol’s ESTANE® 3D TPU S95A powder shows good processability with stable part properties at 50% refresh rates, which are important features for industrial applications.”

“Farsoon’s strength in industrial Laser Sintering Systems motivated Lubrizol to enter into the collaboration.” said David Pascual, Global 3DP Marketing Manager, Engineered Polymers, Lubrizol. “Lubrizol is focused on the Advanced Manufacturing segment, developing open solutions in collaboration with industry leaders such as Farsoon. ESTANE® 3DP TPU S95A powder allows high elastic and flexible parts with great durability and outdoor resistance, thanks to the deep know-how used in the production of this thermoplastic polyurethane specific for powder bed sintering. Using Farsoon’s SLS technology, the sintered items have a whitish color, then can be custom dyed into a wide spectrum of colors. Farsoon and Lubrizol are committed to jointly help customers for using this high performing material-machine combination.”

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media. For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com