With a holistic approach based on four cornerstones – carbon footprint, saving fossil resources, reusability rate and recycling -, specialty chemicals company Evonik has announced the release of new 3D printing materials in its INFINAM® portfolio.

The company understands the key role it has to play as a materials producer and taking steps that may help them produce better materials while protecting the environment. The challenge is even harder for a materials producer given the nature of their activity. That’s why sustainability is pursued in various ways, within the group’s Additive Manufacturing Innovation Growth Field. We remember Sylvia Monsheimer’s words on the topic:

“On the one hand, we are constantly improving our own production processes to make them as efficient and safe as possible. On the other hand, we are putting our innovative power into the development of, for instance, new powder materials to increase their reusability rate during a 3D printing process. As a matter of fact, some of our INFINAM® PA12 powders can be already reused by only replacing the powder needed for the parts of the previous job.”

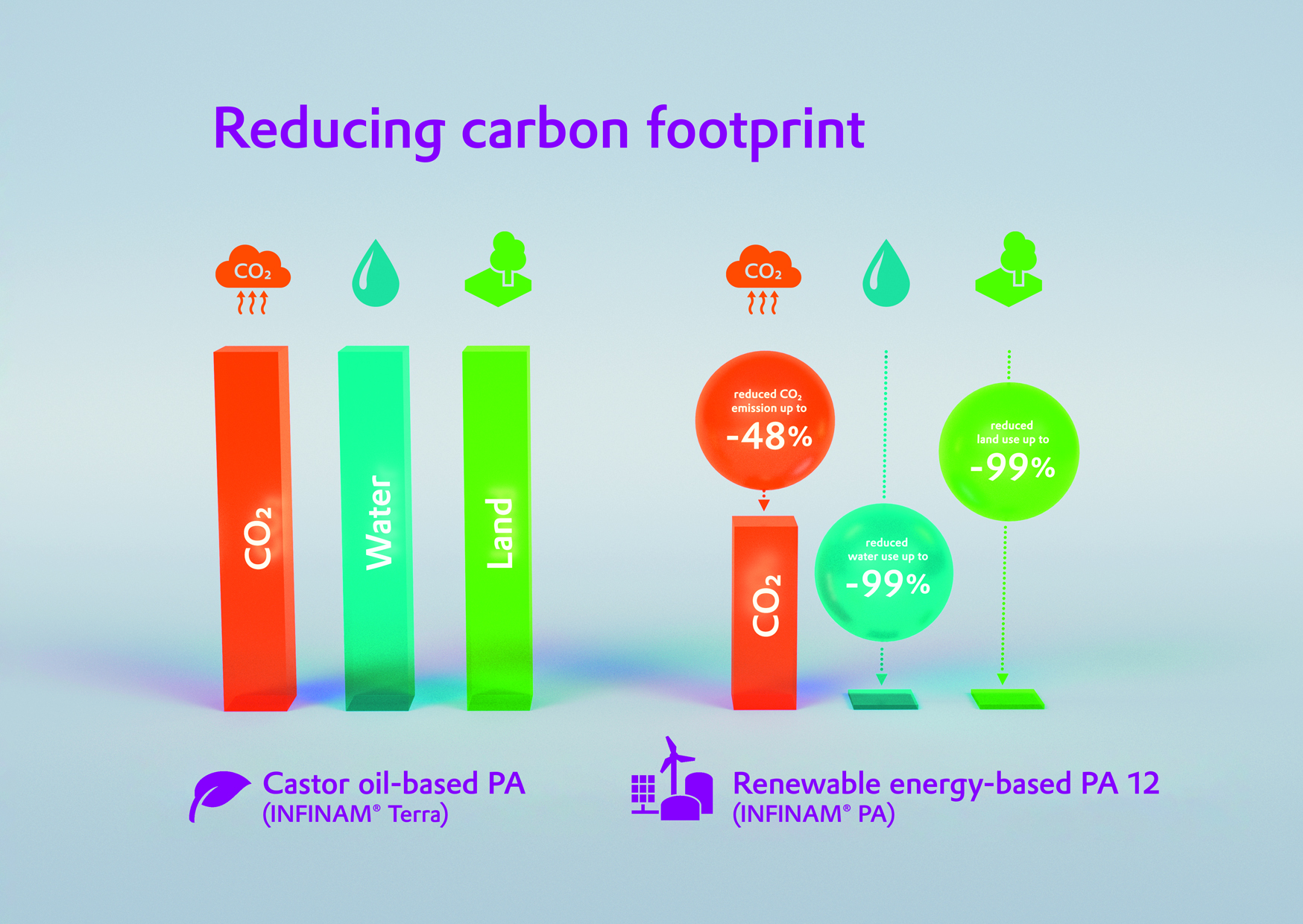

The introduction of a new grade of PA12 powders with significantly reduced CO2 emissions is the first tangible and publicly announced step Evonik is taking to back words with action.

These ready-to-use high-performance materials will replace the previous INFINAM® polyamide 12 materials for all common powder-based 3D technologies such as SLS, HSS or MJF, the company states.

Produced using renewable energies at the Marl Chemical Park, the release of the new sustainable INFINAM® PA12 powders comes along with a certification granted by TÜV Rheinland which conducted life cycle assessments that attest to an improvement in the company’s own carbon footprint of almost 50 percent.

In the overall life cycle assessment, the comparison of the new sustainable material grade is positive even compared with the castor oil-based polyamides of Evonik’s own Terra range.

“Alongside factors such as production efficiency or the reusability of materials, our sustainability approach includes the total life cycle assessments of our materials and their consistent improvement”, says Dr. Dominic Störkle, Head of the Additive Manufacturing Innovation Growth Field at Evonik. “Using green energy and renewable or recycled feedstocks for production, we are able to significantly improve the overall eco-balance of our materials. And we work on end-of-life opportunities for our polymers.”

This might be the first tangible action we see from Evonik but it’s definitely not the last one. Moving forward, we might expect the producer to develop a line of INFINAM® eCO products. “eCO” stands for the company’s goal of avoiding the greenhouse gas carbon dioxide by using renewable or circular raw materials via the mass balance approach. This method enables immediate CO2 reduction in existing plants without changing the quality of the products.

The market launch of INFINAM® eCO is planned for 2023, a press release reads.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com