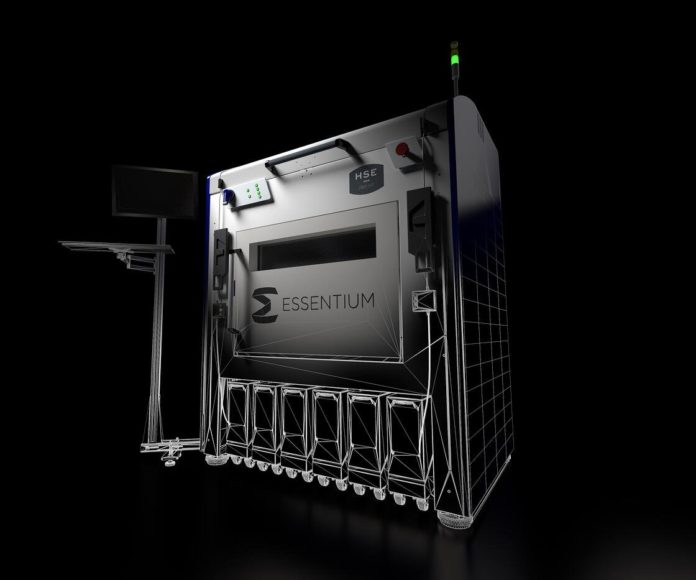

Essentium is challenging the market of independent dual extrusion system (IDEX) with a new 3D printer: the Essentium High Speed Extrusion (HSETM) 280i HT 3D Printer.

Designed and developed to meet the requests of the factory floor, the 3D printer manufacturer claims this solution would be five to 15x faster than competitive offerings – A thought for BCN3D that also provides IDEX-based 3D printers.

With print speeds of over 500 mm/s, the industrial 3D printer would leverage a non-slip, high torque extrusion system with all linear servo motors. Furthermore, unlike most 3D printers that rely on a heated build chamber, the HSE 280i HT 3D Printer has been built with a multimodal heating method. The latter can heat the part and remove the need to wait for the chamber to heat up to start printing.

With independent head on both the X and Y-axis, the 3D printer would address speed time and scalability issues while decreasing post-processing costs.

Its release comes with a new material developed in collaboration with LEHVOSS Group: the Essentium PP-CF. Ideal for silicone and urethane molding applications, the material isa 20% carbon fiber reinforced polypropylene filament made with LUVOCOM® 3F resin. It allows for the manufacture of print chemically resistant, low surface energy 3D printed parts. The parts also deliver greater strength and stiffness than unreinforced polyolefins.

Blake Teipel, Ph.D., CEO of Essentium comments : “The manufacturing industry is increasingly moving toward a leaner and more agile future enabled by AM. This is the beginning of radical change, where billions will be saved through new economic and production models. But this change requires continuous and unrelenting innovation to be able to do things not done before, to make parts that haven’t been made before – and manufacture things that haven’t been manufactured before. This is our goal with the launch of the industry’s first true IDEX machine– we believe the HSE 280i HT 3D Printer is a game-changer giving manufacturers the ultimate machine tool to 3D print at scale.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com