Home =

Thermwood - search results

If you're not happy with the results, please do another search

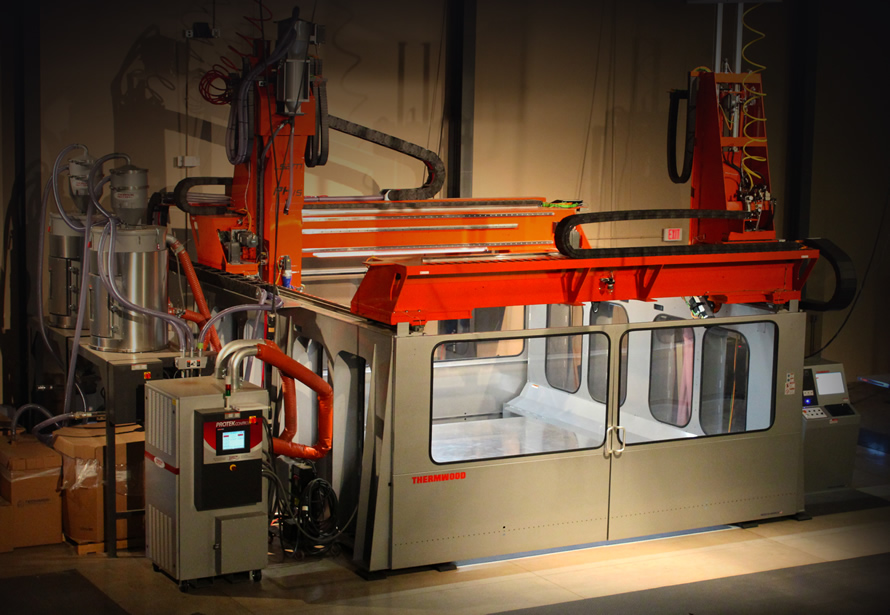

New approach validates Thermwood’s Large Scale Additive Manufacturing capabilities

Among the companies that can pride themselves on developing a true Large Scale Additive Manufacturing (LSAM) is Thermwood. The secret behind the company’s methodology is a patented Vertical Layer Print (VLP) technology.

As the name...

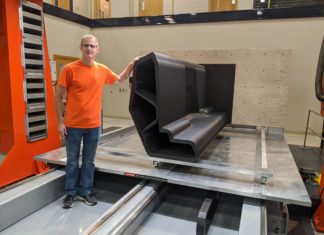

Dennis Palmer on the possibilities of Thermwood’s Large Scale Additive Manufacturing

Another company that positions itself in the large format 3D printing segment is Thermwood. With over 50 years of experience in conventional manufacturing processes – which still constitute much of the company’s core technology...

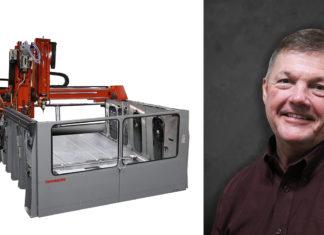

Thermwood’s large-scale additive manufacturing machine improved

It's a one-ton machine and a half-toolhead that Thermwood updated. In addition, thanks to a CNC milling toolhead, one can perceive a hybrid approach to the building of two gantries.

Its use

Called LSAM, the build...

Techmer PM joins Purdue University’s Composites AM and Simulation Consortium (CAMS)

Materials design firm Techmer PM is now part of Purdue University’s Composites Additive Manufacturing and Simulation (CAMS) Consortium. Its presence as a material supplier will help advance research that is being done on large-format...

Download the May/June 2024 edition of 3D ADEPT Mag

This new edition of 3D ADEPT Mag is a reminder that sometimes, real-life principles can unconsciously be applied to manufacturing concepts. Some people often seek drastic changes or new beginnings, believing that only the...

Download the May/June 2024 edition of 3D ADEPT Mag

Download the May/June edition of 3D ADEPT Mag

This new edition of 3D ADEPT Mag is a reminder that sometimes, real-life principles can unconsciously be applied to manufacturing concepts. Some people often seek drastic changes...

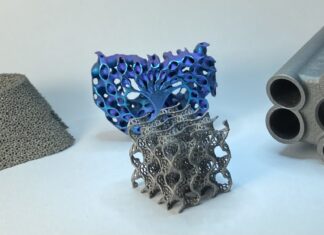

Using composites to replace metal parts in Additive Manufacturing: when and how?

Metal 3D printing has proven so many times its efficiency across applications that it’s almost always mentioned as the route to go in demanding applications. One key limitation experts often deplore is its expensive...

10 technology highlights of 2023 that shaped the Additive Manufacturing world (Part 2)

Updated on January 4th: The article has been updated to reflect the "Arburg" solution in part 4.

2023 has been a very interesting year both from a business and a technology perspective. Whether it was...

2023: Additive Manufacturing, for better or worse (Part 1)

Before starting this “2023 year in review” article, I had a look at what I wrote last year: consolidation through acquisitions & funding dominated the market, materials & software called the tune in the...

Download the September/October edition of 3D ADEPT Mag

Download the September/October edition of 3D ADEPT Mag

There are a couple of things that we have realized since the latest edition. First, a lot of efforts are focused on “Environment” when approaching sustainability in...