Home =

thermwood - search results

If you're not happy with the results, please do another search

FOCUS | Thermwood’s LSAM: What are the key factors of success?

The growing demand for large 3D printed parts implies that Additive Manufacturing users should set realistic expectations when trying to scale up their operations. While the constant comparison between Large Format Additive Manufacturing (LFAM)...

Thermwood @ RAPID+TCT 2024: Broadening the scope of possibility for Large-Scale Additive (and Subtractive) Manufacturing

Starting from roots of thermal coatings & woodworking, morphing into an industry-leading CNC machine tool OEM, and a few years ago bridging into the Additive Manufacturing space; the Thermwood group had a multi-faceted presence...

Thermwood’s Cut Layer Additive is an Additive Manufacturing process that does not 3D print. CEO Ken Susnjara explains why.

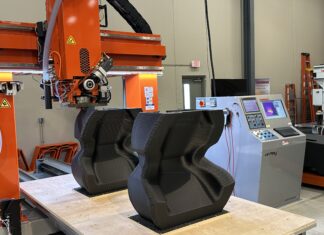

Thermwood has rolled out a new manufacturing approach that brings together its history in CNC routing and its work in large-format additive manufacturing. Named Cut Layer Additive, the new manufacturing process does not 3D...

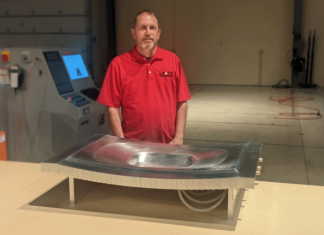

Thermwood continues to demonstrate the viability of its Cut Layer Additive solution – this time with a large aluminum mold

Machine manufacturer Thermwood continues to give users the ability to produce parts with the benefits of the additive process using materials one cannot print or that are difficult to print. One of the AM...

Focus: Thermwood gives hope for the future of recycling, demonstrates superior printed part quality with “Thermal Sensor Layer Automation”

This year’s Rapid + TCT conference in Chicago featured a range of machines and parts, from huge robotic AM machines to the nearly microscopic printed metal pieces used for hearing aids. However, one installation...

Thermwood’s Cut Layer Additive machine is intriguing, as it produces parts that “are similar to large additively printed parts.” Here is how.

An example of application that the machine can deliver, includes a 12-foot-long (3.6m) aerospace tool for the incredibly low material cost of $2,000, in less time than it took to additively print the same...

News RoundUp: Materialise, AddUp, Conflux Technology, Systemic Bio™, Stratasys, Thermwood

This series of news round-up gathers the latest news on facilities’ inauguration, partnerships and M&A.

EOS is the latest AM company to adopt the CO-AM Software Platform

AM company EOS has adopted the CO-AM software platform...

[ FOCUS – Thermwood ]: The arguments that would play to the strengths of LSAM when it comes to sustainability

While we take great care not to use the buzzword “sustainability” without key data, we do recognize that it will take time for OEMs and AM users to provide quantitative analysis that demonstrates how...

Thermwood to conduct another live demo of its LSAM Additive Printer 510 Printing ideal for Molding and Tooling

Industry events often give you the opportunity to discover in-situ how machines operate. Live outdoor demonstrations also show that the machines are not harmful or do not pose a (great) risk to operators’ human...

Thermwood will be printing LIVE on an LSAM Additive Printer 510

Thermwood, one of the three companies providing very large format 3D printing hardware and services with composite chopped Fiber Reinforced Polymer (FPR) pellet materials, will be exhibiting at Rapid + TCT 2022, Booth #2213.

The...

![[ FOCUS – Thermwood ]: The arguments that would play to the strengths of LSAM when it comes to sustainability](https://3dadept.com/wp-content/uploads/2022/10/Thermwood-3D-Printer-3D-ADEPT-324x235.jpg)