420 Stainless Steel is the fourth 3D printing material that AM company Desktop Metal qualifies this year for its binder jetting technology.

Designed for applications across medical, defense, aerospace, and consumer products, the new material can be processed on the manufacturer’s Production SystemTM platform, which leverages patent pending Single Pass JettingTM (SPJ) technology.

Characterized by its high strength and hardness as well as its corrosion resistance to the atmosphere, foods, fresh water, and mild acids when in a fully hardened condition, 420 SS can enable applications such as surgical and dental instruments, ball bearings, gear shafts, pump and valve components, fasteners, gauges, hand tools, and high-end cutlery.

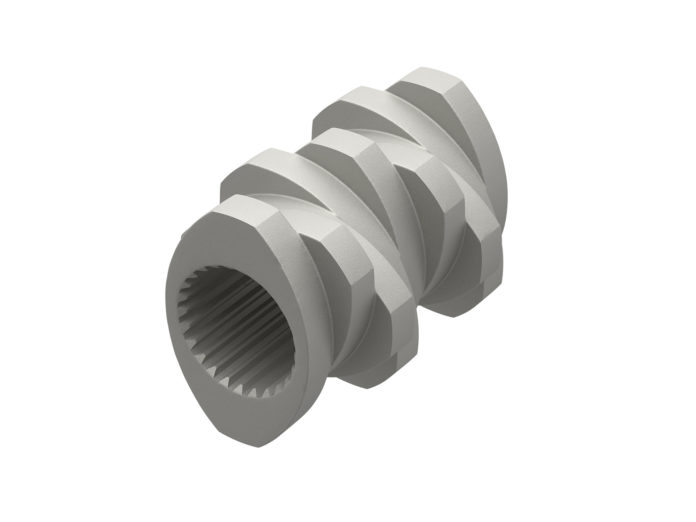

Amid the applications that Desktop Metal has already performed with its new material, one notes a locking articulation bar for medical/surgical applications, a valve nozzle adapter for aerospace and twin-screw extruder mixing elements.

The latter often enable to mix compounding and processing viscous materials. They feature complex lobes around the exterior of the spline that must be optimized for the material being extruded, necessitating a unique mixing element for each different material.

The company explains in a press release that with conventional manufacturing, each of these elements can be complex to produce, often requiring advanced machining techniques, multiple machining setups, and custom fixturing. With Binder jetting on the other hand, the process is simplified and enables the printing of mixing elements in each build, reducing the cost and lead time of production compared to machining.

420 SS is an essential material in these applications for its high hardness and corrosion resistance, ensuring the elements have a long lifetime and the hardness required for extruding a wide variety of materials, the press release explains.

“We believe our qualification of 420 SS and other high-strength alloys will accelerate the deployment of our AM 2.0 solutions among customers looking to successfully mass produce critical parts at scale”, Jonah Myerberg, CTO and co-founder of Desktop Metal comments.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com