This year was said to be the year of polymers in the additive manufacturing market. Given the various centres that opened to foster the development of these materials and the current solutions released by companies, we will certainly witness further advantage of these materials in various applications in the upcoming months.

In the meantime, these are the latest developments from Evonik and 3D Systems.

The specialty chemicals company has developed a new polymer powder for applications in higher temperature range as part of its polyamide 6 series.

Evonik’s new polyamide powder provides high mechanical strength as well as good chemical and temperature resistance to parts. Its heat deflection temperature (HDT B) is around 195°C. Moreover, the powder material stands out for its low water absorption – below 3 percent —, which has a positive effect on processability in 3D printing and the dimensional stability of printed 3D components.

However, confusion is not to be made with its latest polymer material, the PEBA powder, that integrates good flexibility and durability over a wide temperature range from -40°C to 90°C.

“New, ready-to-use materials that are optimally adapted to the individual printer and expand the range of application to higher temperatures move the 3D printing industry one step further toward series production,” says Mark Zhao, founder and CEO of TPM 3D Chinese technology company for Selective Laser Sintering (SLS). “We are seeing strong demand for 3D solutions in the higher temperature range – for example in the automotive and electronics industries. That’s why we were pleased to launch the new temperature-stable material together with Evonik.”

3D Systems’ FabPro Elastic BLK material

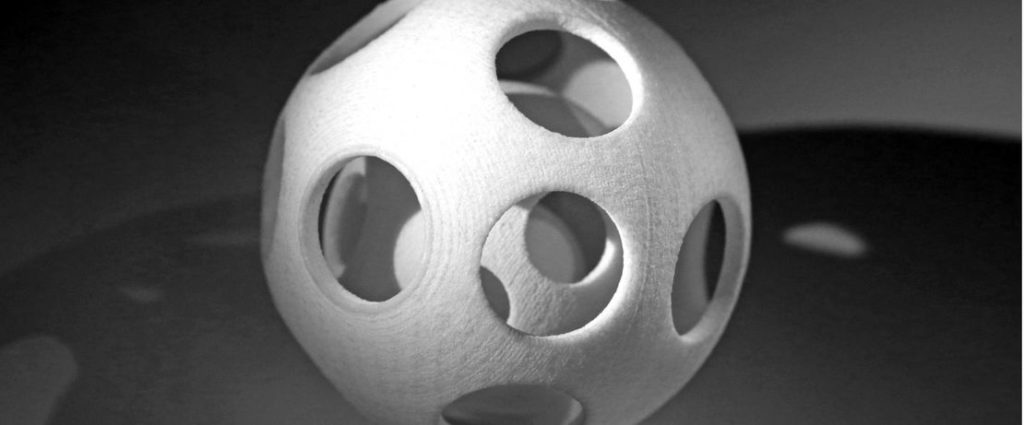

3D Systems on its side is relying on elastomers to ensure design verification and prototyping of rubber-like parts.

The manufacturer of several 3D printers including the DMP Factory and the Figure 4 Standalone provides the market with the FabPro Elastic BLK, that can be processed on its 3D printer FabPro 1000.

This material is now part of a family of several other polymers that range from tough engineering plastics to elastomeric, castable and dental materials and that can be processed on the same FabPro 1000.

3D Systems affirms that the 3D printer delivers speed up to 3X faster than competing systems, high quality output. It works with the 3D Sprint software and brings new levels of affordability to industrial-grade 3D printing.

Seals, gaskets, grips and over-molds are a few examples of applications that can be produced with the material.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email atcontact@3dadept.com