As mentioned in our Formnext recap, one of the highlights of this fifth edition of Formnext was the rise of activities that were given second-rate treatment: post-processing.

Since their series A funding, DyeMansion has managed to go global, and has developed a new series of coloring solutions. Apart from the automotive sector, the German company’s solutions were mostly tailored for lifestyle sectors.

This year at Formnext 2019, with the release of DyeMansion Powerfuse S, the company showcases a key focus on industrial needs.

DyeMansion Powerfuse S

The company’s first coloring solution for Powder Bed Fusion parts was in 2015. Two years ago, the company unveiled a full line of solutions that covered all post-processing steps.

The company affirms then that the DyeMansion Powerfuse S is “the system behind their proprietary VaporFuse Surfacing technology and the first chemical smoothing solution that proves to be clean and industry-ready on the basis of obvious characteristics.”

The Powerfuse S integrates a fully automatic loading option, connectivity and batch tracking features. Although we were not given the type of material profiles that were already integrated, DyeMansion has inserted validated and developed programs for the most widely used materials in the industry, in order to ensure compatibility with various solutions.

Furthermore, there is always room for insertion other types of materials.

The integration of such type of process parameters ensures flexibility and a seamless integration with existing production processes such as the DyeMansion Print-to-Product workflow.

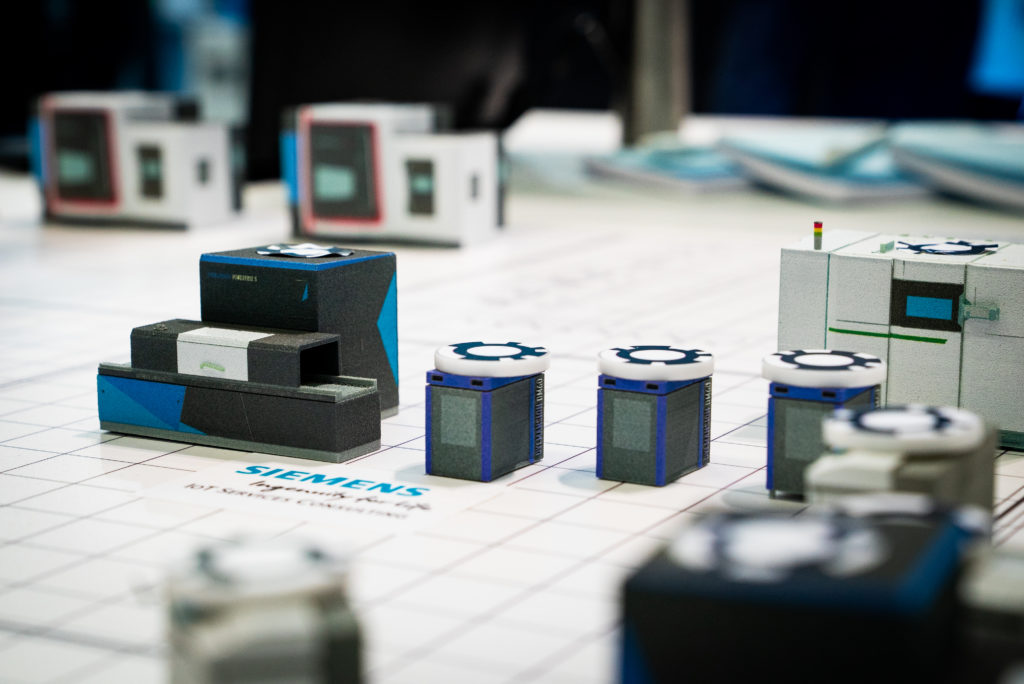

Moreover, the Powerfuse S is also included in the Siemens Automation Technology for digital AM factory.

According to Felix Ewald, CEO & co-founder at DyeMansion, the development of this new solution will set new standards in the industry and proves that the company is able to offer solutions at the highest industrial level.

How DyeMansion addresses sustainability

Sustainability has not only become a trendy word in the industry. The lack of alternatives sometimes raises health issues in the production environment.

In that sense, post-processing specialists are uniquely positioned to address this issue.

DyeMansion therefore brings the VaporFuse Eco Fluid solvent to the industry. Different from solutions with corrosive solvents or acids, this solvent is inoffensive for both the operator and the environment.

Ideal for the processing of plastics with food contact according to regulation (EU) 10/2011, the solution is continuously used in a closed loop and automatically recovered by the system. More importantly, it does allow a sustainable contact-free process without chemical waste

DyMansion’s solutions displayed at Formnext 2019 show that the company is ready for the future of manufacturing. More importantly, the company’s ability to address sustainability, a key issue of today’s manufacturing, shows that they are now playing in another league.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com