Assonic Dorstener Siebtechnik GmbH, Solukon Maschinenbau GmbH and ULT AG, three Germany-based SMEs join forces to address challenges operators faced when it comes to establish AM as an industrial process for serial production.

For operators of the SLM technology, it is crucial to develop efficient manufacturing practices. This manufacturing technology often raises issues related to powder processing and handling. For this vital step of the manufacturing process, Assonic Dorstener Siebtechnik GmbH, Solukon Maschinenbau GmbH and ULT AG decided to create AM Powder Plus (AMP+).

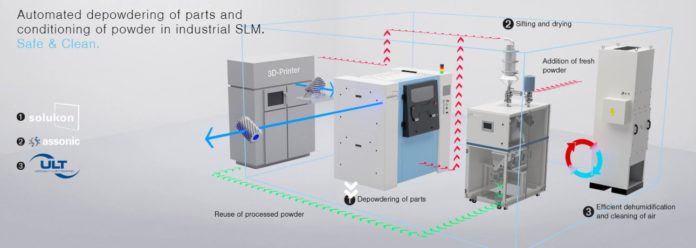

The new network delivers a comprehensive range for highly automated parts and powder processing and handling in the SLM process.

Assonic Dorstener Siebtechnik GmbH is part of a bigger group that has been established ten years ago. The company has developed a process that enables to enhance the material quality for several high-performance products. The company has acquired extensive experience in screening media for innovative processes.

ULT AG specializes in extraction and filtration technology for the removal of airborne pollutants. ULT’s product portfolio ranges from mobile extraction units for manual work places, to stationary systems for production lines, up to air ventilation systems for complete facilities, or the support of large devices. In addition to turn-key products, the company develops and commercializes configured solutions for customized applications and conditions.

Solukon Maschinenbau GmbH develops peripheral post-processing equipment for additive manufacturing technologies. The company has worked hard to raise awareness on the modest priorities given to post-processing and has developed automated post-processing systems to help operators moving towards industry 4.0.

The AMP+ partners joined their respective experience and strengths to fill the gap that exists between the completion of printing and the start of post-processing. According to the partners, existing challenges operators often faced, include inefficient manual work, unnecessarily high consumption of costly metal powders as well as explosion hazards and of airborne pollutants which can be dangerous for health and production facility.

In the video below, Alexander Jakschik from ULT AG, Rüdiger Tüshaus from assonic Dorstener Siebtechnik and Andreas Hartmann from Solukon discuss this solution. A solution, that in the end, “includes the collection, sifting, reprocessing and drying of surplus powder in the metal PBF process with automated component removal and depowdering for clean transfer to post-processing. Unexposed powder is returned to the PBF process in a fully processable state, assuring occupational health and safety, dust explosion protection, and a clean working environment.”

Video interviewed carried out at Formnext 2019 by 3D ADEPT Media.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media. For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

Assonic Dorstener Siebtechnik GmbH, Solukon Maschinenbau GmbH and ULT AG, three Germany-based SMEs join forces to address challenges operators faced when it comes to establish AM as an industrial process for serial production.

For operators of the SLM technology, it is crucial to develop efficient manufacturing practices. This manufacturing technology often raises issues related to powder processing and handling. For this vital step of the manufacturing process, Assonic Dorstener Siebtechnik GmbH, Solukon Maschinenbau GmbH and ULT AG decided to create AM Powder Plus (AMP+).

The new network delivers a comprehensive range for highly automated parts and powder processing and handling in the SLM process.

Assonic Dorstener Siebtechnik GmbH is part of a bigger group that has been established ten years ago. The company has developed a process that enables to enhance the material quality for several high-performance products. The company has acquired extensive experience in screening media for innovative processes.

ULT AG specializes in extraction and filtration technology for the removal of airborne pollutants. ULT’s product portfolio ranges from mobile extraction units for manual work places, to stationary systems for production lines, up to air ventilation systems for complete facilities, or the support of large devices. In addition to turn-key products, the company develops and commercializes configured solutions for customized applications and conditions.

Solukon Maschinenbau GmbH develops peripheral post-processing equipment for additive manufacturing technologies. The company has worked hard to raise awareness on the modest priorities given to post-processing and has developed automated post-processing systems to help operators moving towards industry 4.0.

The AMP+ partners joined their respective experience and strengths to fill the gap that exists between the completion of printing and the start of post-processing. According to the partners, existing challenges operators often faced, include inefficient manual work, unnecessarily high consumption of costly metal powders as well as explosion hazards and of airborne pollutants which can be dangerous for health and production facility.

In the video below, Alexander Jakschik from ULT AG, Rüdiger Tüshaus from assonic Dorstener Siebtechnik and Andreas Hartmann from Solukon discuss this solution. A solution, that in the end, “includes the collection, sifting, reprocessing and drying of surplus powder in the metal PBF process with automated component removal and depowdering for clean transfer to post-processing. Unexposed powder is returned to the PBF process in a fully processable state, assuring occupational health and safety, dust explosion protection, and a clean working environment.”

Video interviewed carried out at Formnext 2019 by 3D ADEPT Media.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media. For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com