Aurora Labs successfully achieves high-speed titanium printing & high-density aluminium printing

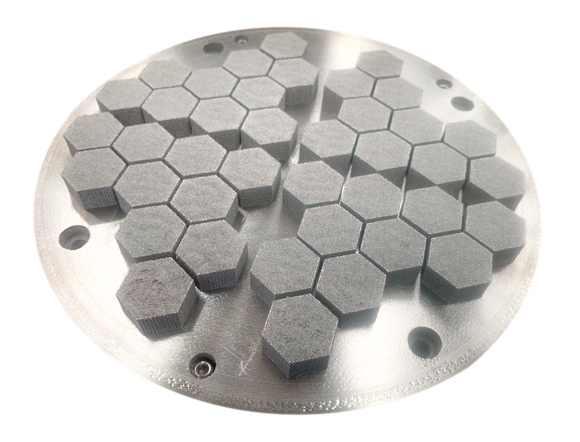

Australian-based company Aurora Labs Limited has achieved something new with its Multilevel Concurrent Printing (MCP™) technology. The company manufactures a series of 10mm high, titanium hexagon parts. The test production only took 20 minutes on a 200mm plate, and showed the capacities of the manufacturer’s MCP™ technology, which will feature in the company’s RMP-1 3D printer.

As a reminder, the company had proven scalability of the RMT using Multilevel Concurrent Printing (MCP) process. The test production had demonstrated that its technology can print speeds of 113kg/day.

As far as this titanium printing test is concerned, Managing Director, David Budge, said the test is another example of the technology’s ability to manufacture complex shapes at high speeds. “This as an exciting test for us, following on from our result in February that achieved 3D print speeds of 113 kilograms per day,” Mr Budge said. “This outcome will give our partners and future customers confidence that we have an additive manufacturing solution that can deliver the Holy Grail of rapid 3D printing, which is looking to revolutionise the production of parts in a whole range of applications.”

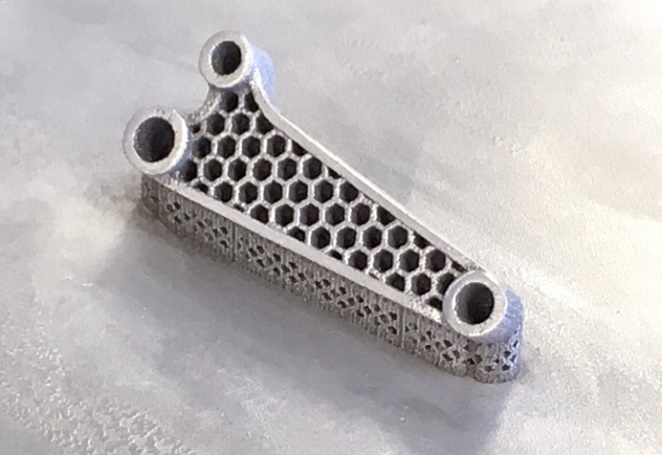

Following the high-speed titanium printing, Aurora Labs has also completed a successful print run of high-density aluminium. The first test run, using the Company’s prototype Alpha RMT machine, manufactured an aluminium part at a density of around 99%. “This is an early stage result and we are expecting to achieve further significant manufacturing improvements. Aluminium is in high demand for a range of high-value applications such as the Automotive, Aerospace and Heat Exchanger industries where consistent quality and meeting tight specifications is required,” Mr Budge said.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});