After raising $5 million in Placement at $0.38 per share, Aurora labs ensured that the funds will primarily be used to foster the development of Rapid Manufacturing Technology (RMT), a technology that has already proven its capabilities in various industries including the mining industry. Less than 4 days after this announcement, the Australia-based company announces it has proven scalability of the RMT using Multilevel Concurrent Printing (MCP) process.

Indeed, the company has completed the current phase of testing of its technology which would be capable to achieve print speeds of 113kg/day. This rate is approximately 55 times higher than what is observed on the Market.

A quick comparison with current 3D printing solutions of the market

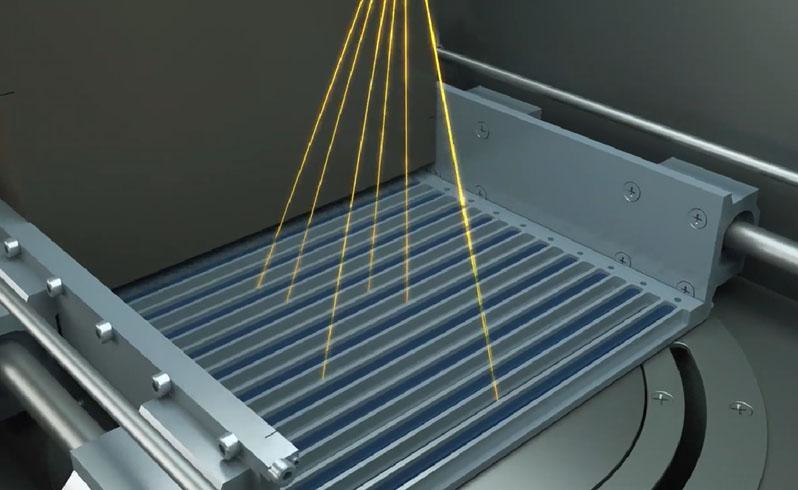

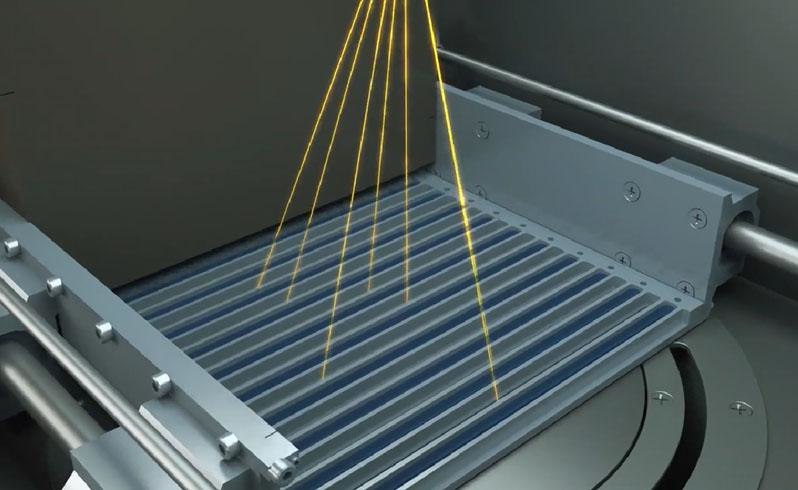

The company explains that when it comes to “traditional 3D printing”, a digital part (3D model) is run through software which slices the digital part up into a series of very thin layers. The printer puts down a layer of powder on the print bed and then the first “slice” of the part is fed digitally to the printer and an energy beam (laser, e-beam or other) scans the surface of the powder bed, melting and fusing the powder in the exact shape and dimensions of the slice. This process is repeated and the next layer fuses to the previous one, forming a homogenous part. This process is repeated until all the slices have been printed. Once printed what is left is a complete replication of the digital part that has now been printed out of metal.

However, in Aurora’s unique MCP process, multiple layers of powder are laid down at the same time. During the powder laying process there is an area behind each individual powder gate where printing can take place (operative surface), meaning that printing can occur on these multiple operative surfaces simultaneously (Multilevel Concurrent Printing). By using a number of gates, MCP printing can be significantly faster than traditional 3D printing processes.

This comparison also raises the attention on the fact that, the more the market grows, the more first 3D printing technologies are now considered “traditional”. That’s pretty funny when we know that, we use to compare all of them with “traditional” processes. Anyway, the potential of this technology shows that Aurora Labs does not only become big, the company is providing the best resources to distinguish itself in this 3D printing race, and it does it pretty well. We can’t wait to see applications achieved based on the MCP process.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com