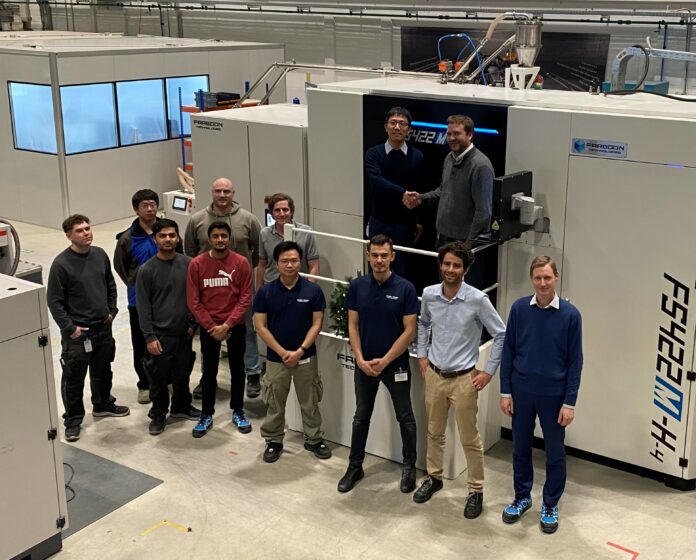

APWORKS, an AM service bureau that focuses on delivering metal 3D printing applications, has added a new Laser Powder Bed Fusion machine to its portfolio: the FS422M-4 3D printer.

Developed by Farsoon, the new machine is a medium-large scale metal laser sintering system developed to offer continuous AM production through scalability and modularization. Designed under the concept of CAMS – Continuous Additive Manufacturing Solution, the machine integrates a build envelope of 425 x 425 x 550 mm and delivers high productivity with a Quad 500-watt lasers option.

Apart from the build station where the sintering process takes place, the industrial 3D printer can be supported by a permanent filtration system, a breakout station, a powder refill unit and a sieving station.

“We are very excited to take this step with FARSOON. We believe that it will enable us to scale our production of high-quality Scalmalloy parts in the most economical way possible. For the last ten years we have focused on developing applications of Metal Additive Manufacturing (AM) which add value for our customers. We design and produce products with the highest performance and quality, supporting customers across a wide range of industries. Our goal has always been to expand the scope of Metal Additive Manufacturing (AM) applications, which has generally been limited by the economics of the process. The total cost of ownership coupled with the productivity of the AM systems we use is the biggest factor in defining which applications areas we can add value in. We believe that the Farsoon FS422M-4 machine offers us a step change in overall cost of ownership and productivity, enabling us to target applications which were previously not economically attractive. Through this cooperation with Farsoon we intend to further scale the scope of our business, empowering more customers to reap the benefits that this technology has to offer,” Jon Meyer, CEO of APWORKS GmbH explains.

The collaborative efforts between FARSOON Europe GmbH and APWORKS GmbH extend beyond the immediate transaction, focusing on long-term innovation, increased production capacity, reliable and sustainable series production, and the optimization of Scalmalloy processing for groundbreaking additive manufacturing applications in the aerospace industry, a press release reads.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com