Home =

Smart Powder Recuperation technology - search results

If you're not happy with the results, please do another search

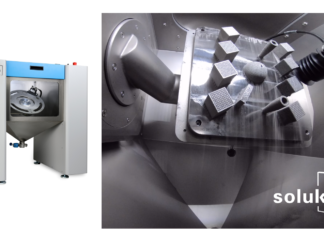

The DMG MORI Academy relies on Solukon’s technology for the removal of powder from metal 3D printed parts

We have just learned that DMG Mori, one of the largest machine tool manufacturers, relies on Solukon’s depowdering systems for the removal of powder from its laser-melted metal parts. The automated systems SFM-AT350 and SFM-AT800-S are use...

Solukon’s SPR-Pathfinder® Software to Bring Depowdering of 3D Printed Parts to the Next Level

The development and improvement of depowdering solutions is not solely based on machines. A key part of their functionality and their ability to achieve an automated and repeatable work is based on the software...

Solukon’s automated depowdering system for large 3D printed parts becomes part of the Launcher fleet

Solukon’s automated depowdering system for extraordinary large and heavy rocket parts has found a new home at Launcher’s facilities. Launcher is an aerospace company that develops one of the most efficient rockets and orbit...

Solukon continues to enhance depowdering phase of metal 3D printed parts with new automated depowdering system

The new machine completes a portfolio that already includes four systems designed for metal parts, each of them optimized for different part sizes and applications.

We caught up with Andreas Hartmann, CEO and CTO...

Solukon adds new feature to its entry-level automated depowdering system for medical 3D printed parts

One of the most widely known automated depowdering systems developed by Solukon is the SFM-AT800S solution but let us not forget that the company also has an entry level machine that it has been...

Solukon and Festo to explore how far they can push the level of automation for depowdering of 3D printed parts forward

Solukon and Festo joined forces in a development project to enhance efficiency when it comes to the depowdering of laser-melted metal parts. An intriguing announcement when one knows that Solukon’s proprietary Smart Powder Recuperation...

SLM Solutions & Solukon partner for depowdering of metal 3D printed parts

Expert in depowdering of 3D printed parts Solukon is determined to work closely with its partners to bridge the gap between the printing process and all steps related to the post-processing phase.

The latest partnership...

Depowdering of Aerospace 3D Printed Parts: Solukon integrates new features to its automated powder removal systems

Machine manufacturer Solukon has just announced new upgrades for its automated powder removal systems. The upgrades concern the SFM-AT1000-S and the SFM-AT800-S units.

As a reminder, the Germany-based company has been developing automated depowdering systems...

More on “depowdering” for medical 3D printed parts

Remember when we explained that post-processing in additive manufacturing of medical parts is a matter of liability? Well, we recently attended a webinar that confirmed again this statement, but most importantly, gave attendees further...

This 3D printed electric motorcycle saves more energy thanks to smart two-wheel drive

The team used Stereolithography (SLA), Selective Laser Sintering (SLS) and Selective Laser Melting (SLM) to 3D print several design parts of the casing and structural components

As part of a Swiss student project named ETHEC...