Created to address the challenges of the Swedish pulp and paper industry, when it comes to fiber suspensions, Ramén Ball Sector Valves are used today as isolating and control valves for fluids, gases, turbid media and sludge.

Manufacturing these valves usually requires the use of casting and machining (of bar stocks). Under the leadership of Managing Director Per Wennersten, Ramén Valves decided to explore the use of AM in 2012. Their goal was to optimize the production of valves by integrating new technologies into their processes.

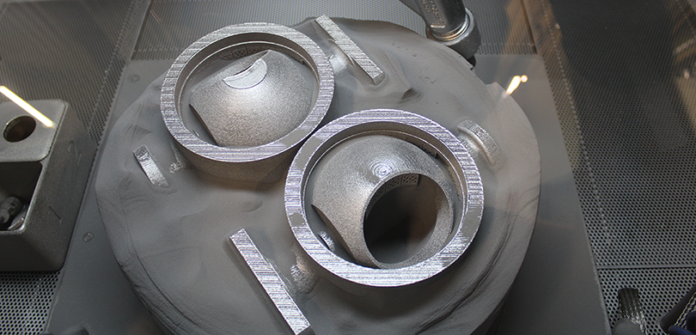

Their choice went to Arcam Electron Beam Melting (EBM) and titanium, a metal that is commonly used in pulp and paper applications. The team started then to collaborate with AIM Sweden, a service bureau specializing in EBM technology and its industrial applications. AIM Sweden uses GE Additive EBM technology in their production facility.

“The ball sector valves from Ramén Valves are a very good example of where the EBM process can really add value,” said Stefan Thundal, AIM Sweden’s CEO. “First, many of these valves are used in critical applications, where confidence in material properties is paramount. Second, these valves are often large, bulky components, and for such components, the EBM process excels, both in productivity and providing parts free from residual stress. Finally, we can offer Ramén Valves significantly shorter lead times.”

Why the use of AM makes sense

We learn from Ramén Valves that AM helps them improve the functionality of their valves, reduce lead times in production and develop retrofitting applications.

By adapting the build length of the valve to improve its design, Ramén Valves began creating valves with extended functionality. Moving forward, the company hopes to increase the productivity of existing processes by adding extra functions.

As traditional casting was often conducted in Asia, relying on local production with AM helped the team reduce long lead and shipping times for parts. A Ramén Ball Sector valve for the pulp and paper industry can be delivered within four weeks compared to two months with more traditional manufacturing, the company explains.

As far as retrofitting applications are concerned, lots of valves for old pipes are not made anymore. Instead of spending a lot to change or build new pipes, many companies want to stick with their current systems.

This requires making exact copies of valves that are not made anymore. Because these valves are custom-made, it’s not practical to make lots of them using traditional methods like casting and machining. However, being able to 3D print them when needed, even just one at a time, has opened up a new market for Ramén Valves.

As you may guess, certification and cost remain two of the biggest challenges the company faces. “We think that the certification of 3D-printed parts in our industry could help to bring prices down and grow the market. It’s currently not possible to get a materials certification for 3D printed parts, as you can for casted or machined parts,” said Wennersten.

“There has been some development towards certification thanks to compliance and certification organizations such as TÜV, Lloyds and DEKRA, but there is still no definitive method for having the 3D printed parts in pressurized conditions. Without certification, it is impossible to obtain a CE Mark and we are unable to sell the valves in Europe.”

Ramén Valves in-house certification, distributed with units sold, remains limited because it’s not verified by a third party hence current discussions with DEKRA.

Cost and acquisition of 3D printers

The current high costs also make it difficult to purchase their printers not to mention that the market is currently not yet big enough to justify purchasing an in-house machine. For this reason, the company prefers to rely on the capabilities of a service bureau like AIM Sweden.

Moving forward, there is a lot of interest and potential to improve output in coming years. “While the focus now is on complex geometries, it’s hoped that the ability to use these valves for pressurized systems in the coming years will open doors to new applications and markets,” Wennersten concluded.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com