Xact Metal™, a manufacturer of affordable metal 3D printers, partners with Uddeholm, a voestalpine company, to supply Corrax tool steel for additive manufacturing, in support of the company’s expansion into the tooling and molding space.

This new material would help Xact Metal customers achieve corrosion-resistant, cobalt-free tool and mold steel applications with an A1 surface finish post-polishing.

“We are proud of our partnership with Uddeholm,” said Juan Mario Gomez, Xact Metal CEO, “which grants us the ability to offer their revolutionary Corrax metal powder. This intersection between our affordable, high-performing 3D printing technology and Uddeholm’s material expertise is the point where the adoption of additive manufacturing can begin serving the tooling and molding industry. Uddeholm’s rich history and practical knowledge in the steel industry brings a legacy of excellence and innovation to our collaboration.”

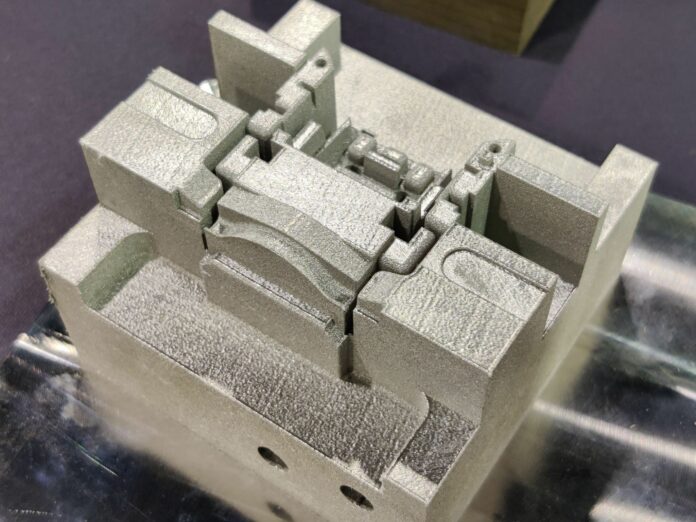

Traditionally, molders and mold makers faced limitations in creating optimal internal structures for molds due to the constraints of traditional manufacturing methods. This solution aims to support the adoption of AM in the tooling and molding industries and marks a significant milestone in additive manufacturing, tooling, and molding industries, empowering molders and mold makers with unprecedented capabilities with metal 3D printing.

“We are excited to be partnering with Xact Metal,” said Kevin Rochford, Vice-President of Sales from Uddeholm. “This partnership not only signifies a milestone in additive manufacturing but also brings in a new era of possibilities for the mold and tooling industry, where complexity meets efficiency, and tradition meets innovation. With our long history in the steel industry, this is a natural step forward for Uddeholm.”

In addition to the technological advancements, the environmental benefit of Corrax powder is noteworthy. Uddeholm’s sustainable production practices prioritize using fossil-free electricity to achieve a fossil-free powder manufacturing process.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com