3D printing has brought a significant value in the way medical professionals or non-medical experts produce prostheses. Virginia-based researchers have been looking for new ways to improve the use of 3D printed prosthetics by those who wear them.

According to a Virginia Tech professor and his team of undergraduate student researchers, one limitation of the current models of 3D printed prosthetics is the lack of personalized electronic user interfaces. The idea has been initially developed for children with amniotic band syndrome.

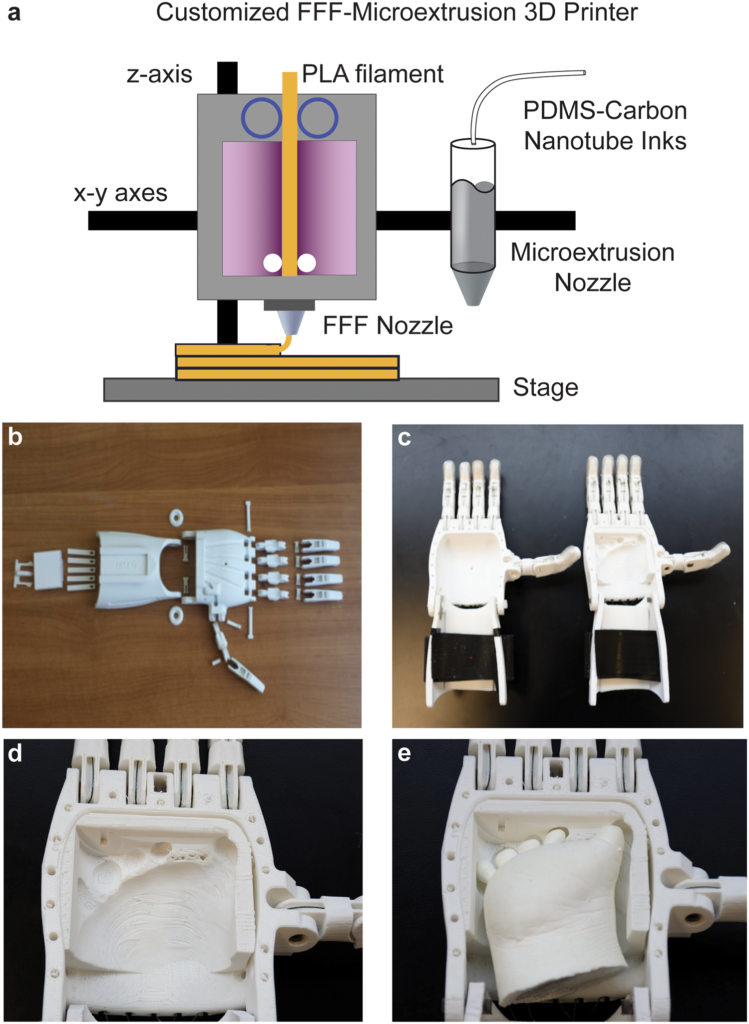

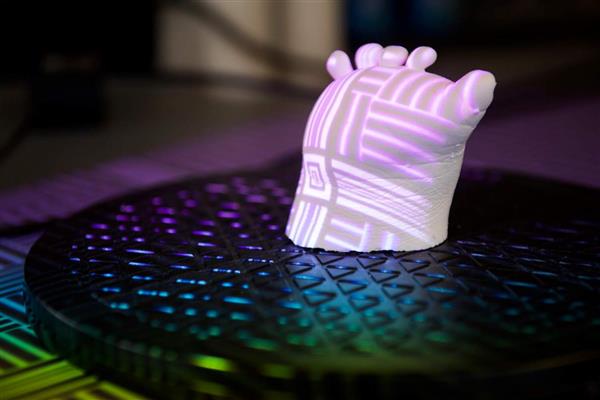

The study aims to establish computer-aided design and manufacturing methods for producing personalized anatomically conformal systems, such as wearable devices and human-machine interfaces (HMIs).

“Personalizing and modifying the properties and functionalities of wearable system interfaces using 3D scanning and 3D printing opens the door to the design and manufacture of new technologies for human assistance and health care as well as examining fundamental questions associated with the function and comfort of wearable systems,” said Blake Johnson, a Virginia Tech assistant professor in industrial and systems engineering.

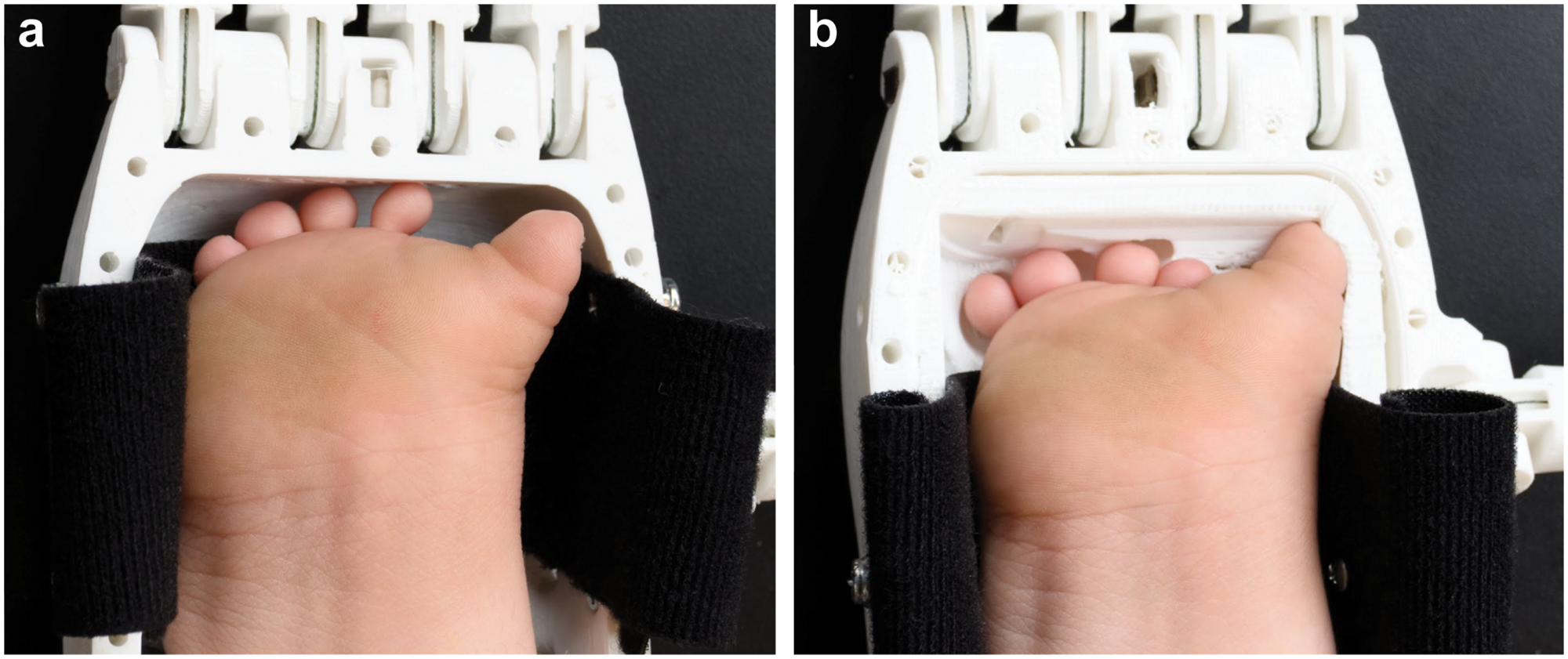

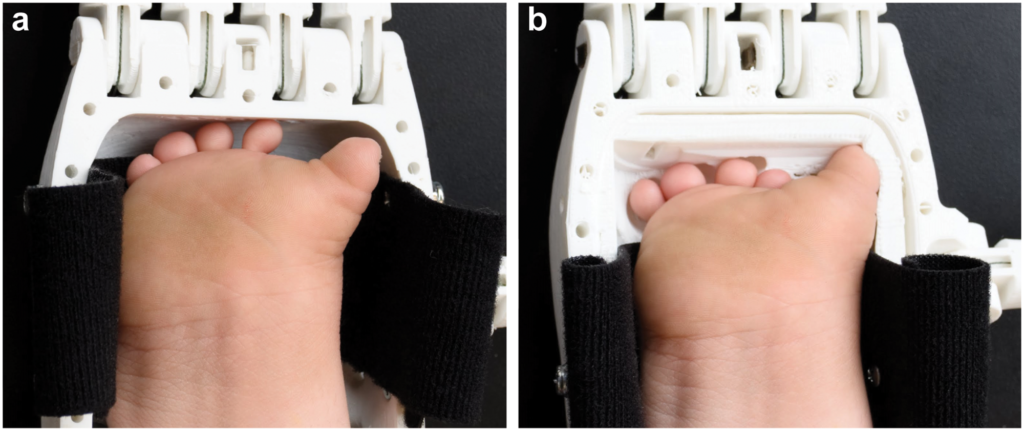

According to the research, the integration of electronic sensors at the intersection between a prosthetic and the wearer’s tissue enables to gather information related to prosthetic function and comfort, such as the pressure across wearer’s tissue. Information that can help improve iterations of these prosthetics.

Furthermore, rather than integrating them manually after the printing process, it seems that the integration of materials within form-fitting regions of 3D printed prosthetics would be more benefit for the fusion between the wearer’s tissue and sensors at different locations across the form-fitting interface.

“The mismatch between the soft skin and the rigid interface is still a problem that will reduce the conformity,” said Tong, one of the engineering graduate students of the team. “The sensing electrode arrays may open another new area to improve the prosthetics design from the perspective of distributing a better balance of pressure.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email atcontact@3dadept.com