New partnership will lead to new solutions for the automotive industry

Specialty chemicals company Evonik and chemical and mineral specialties group LEHVOSS Group have announced a partnership to create new material solutions for industrial 3D printing. Being both material producers, this partnership shows that expertise and commitment to delivering customer-centric products come first – or at least are beyond the competitive nature of companies.

On the one hand, LEHVOSS will harness Evonik’s PA613 polymer chemistry to develop its own 3D printing formulations under its own LUVOSINT® product branding.

On the other hand, effective September 1st, LEHVOSS includes Evonik’s polymer powder INFINAM® PA 6005 P (PA613) in its own product portfolio since September 1, 2023.

“The collaboration with LEHVOSS is very special for us, because this is the first time in our three-decade history that we are entering into a partnership with another material manufacturer. The expert-team at LEHVOSS is well positioned to produce specialty formulations that enable new 3D applications,” says Sylvia Monsheimer, head of industrial 3D printing at Evonik.

In case you don’t know, the polymer powder INFINAM® PA 6005 P is based on polyamide 613. The material can be processed by selective laser sintering (SLS) 3D printing and is produced using Evonik’s own special precipitation process at the Marl Chemical Park in Germany. It is suitable for 3D applications in the higher temperature range.

Compared to other difficult-to-process materials of the polyamide 6 family, INFINAM® PA 6005 P has an impressively low water absorption rate – less than 3 percent – which has positive effects on both the processability in the 3D printing process, and the dimensional stability of the printed component, a press release reads.

The development of new PA613-based formulations for 3D printing

The LEHVOSS Group is known for its LUVOSINT® and LUVOCOM® 3F product lines in the AM industry. These products deliver material properties that can be processed on Powder Bed Fusion, Fused Filament Fabrication (FFF) and Fused Granulate Fabrication (FGF) machines.

“Partnering with Evonik and using their excellent base polymer made it easier to develop a customized product for our customers’ technical applications,” says Dr. Stefan Schulze, 3D printing team leader at LEHVOSS.

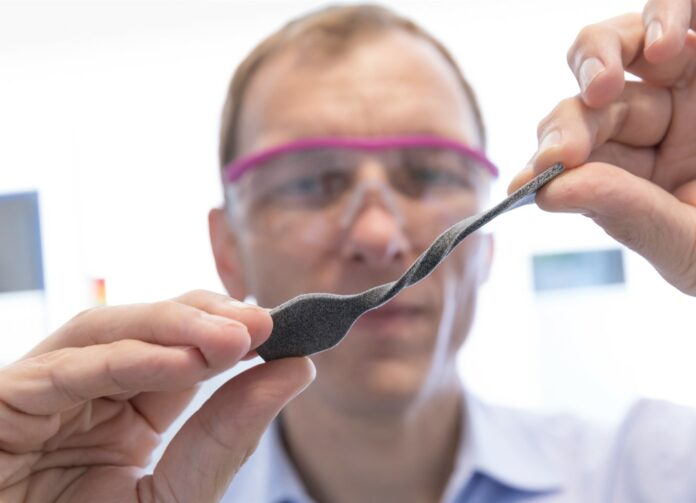

In this specific case, LEHVOSS has developed a carbon fiber reinforced powder variant for laser sintering created from Evonik’s PA613 base polymer. Marketed under the brand name LUVOSINT® PA613 9711 CF, the product features special carbon fibers compounded into the individual polymer particles. Carbon fibers bonded in this way are compliant with applicable occupational safety regulations. Additionally, by including Evonik’s unreinforced INFINAM® PA 6005 P into its own product distribution portfolio, LEHVOSS now offers customers both of these great formulations, all from one supplier.

With this partnership, Evonik remains faithful to its goal to develop high-performance materials for all major polymer-based 3D printing technologies.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com