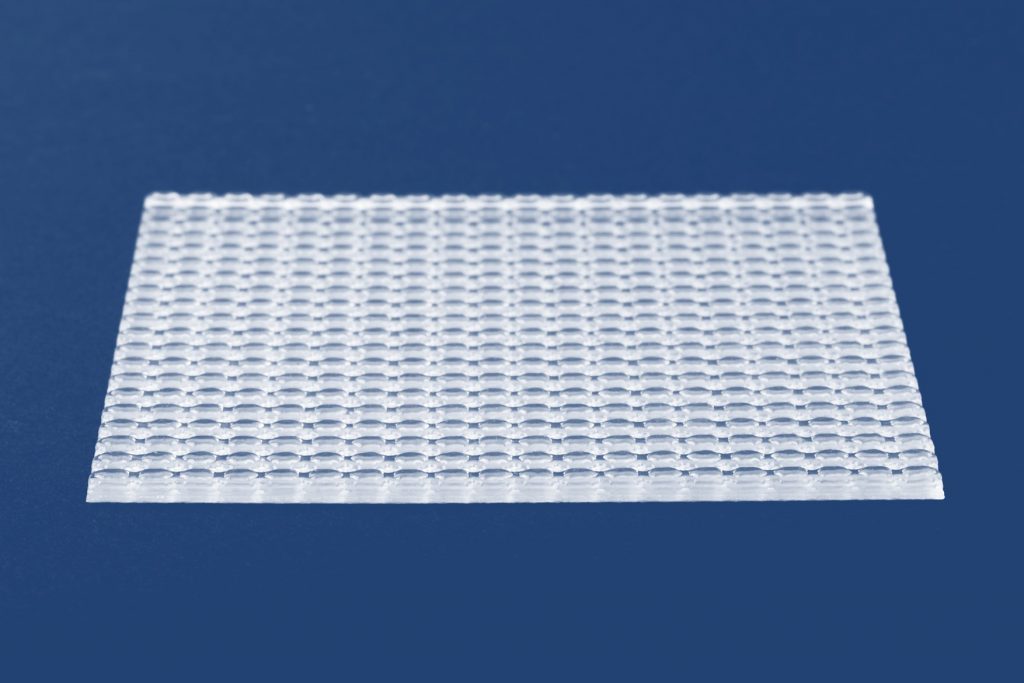

The ACEO campus will help users to deeply understand ACEO technology, an inkjet 3D printing that will function with silicones, combining both high precision and freedom in design.

Through this initiative of Wacker Chemie, and to ensure best results with this material, ACEO® developed both hardware and software for their unique technology.

3D printing with silicones with first-hand experience

In small groups (up to 4 people), Open Print Lab could offer programs that consist in theoretical and printing sessions from additive manufacturing basics to advanced design.

On the web shop, users from all over the world could upload their designs, and after the quote, 3D print their parts and ship them everywhere around the world.

Dr. Pachaly, Head of Project 3D Printing at Wacker Silicones, declares about ACEO campus: “Information and education across industries are key to understanding the variety of opportunities and applications offered by the ACEO technology. We want customers to understand how our solution matches their needs.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});