UpNano, a manufacturer of 2-photon polymerization (2PP) 3D printers, has explored the use of a new resin on its machines: the bioink Hydrotech INX© U200. Developed by material specialist BIO INX headquartered in Belgium, the new material enables the fabrication of complex and versatile organ- or lab-on-chip designs.

The results of this collaboration now allow to add an additional layer of complexity to a bioprinted construct by the smart combination of multiple biocompatible materials. In this respect, versatile cancer-on-chip models are possible by combining the newly launched resin with cell-encapsulating gelatin-based hydrogel Hydrobio INX© U200. The latter would be the “first commercially available high resolution bio ink that offers cell interactivity”.

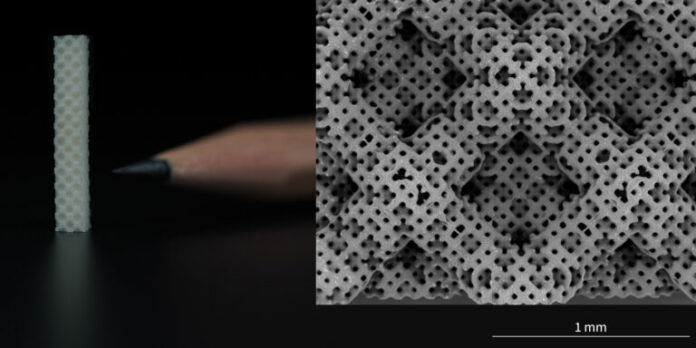

Macrostructures with micrometer-precision

With the release of Hydrotech INX© U200 the two companies demonstrate their success in developing a versatile material that enables 2PP 3D-printing of macrostructures with micrometer-precision. The material has been certified according to ISO 10993-5, confirming its excellent biocompatibility.

Jasper Van Hoorick, CEO of BIO INX, comments: “In combination with the fact that the material is completely bio-inert, its robust characteristics make Hydrotech INX© U200 the ideal choice for organ-on-chip applications.”

The material can be processed on UpNano’s NanoOne 2PP-printer, a high-resolution 3D printing system based on multiphoton lithography and which delivers a throughput of up to 450 mm³ per hour. Furthermore, the NanoOne Bio is specifically adapted for printing with living cells and under sterile conditions – and thus a congenial partner for the most challenging task in bioprinting: fabrication of complex 3D scaffolds for cell cultures whilst embedding living cells into these structures in one simple set-up.

“Combining these steps can easily be done,” explains Denise Hirner, COO and co-founder of UpNano, “by using the NanoOne Bio in combination with the two bioinks Hydrotech INX© U200 for the inert structure and Hydrobio INX© U200 for living cells in 3 dimensions.”

In fact, whilst the Hydrotech-bioink is perfectly optimized for the high-resolution fabrication of bioinert but biocompatible microstructures, the Hydrobio-bioink is a water-soluble natural hydrogel that allows the direct transfer of cell cultures from 2D-culture plates into complex 3D-structures. It has been specifically developed for the encapsulation of multiple cell types thereby allowing the generation of complex 3D-microtissues.

In addition to lab-on-a-chip devices with embedded living cells, surface structures resembling natural tissues (biomimetic structures) such as liver lobules or intestinal villi can now be created inside a microfluidic channel on a chip, and living cells at various densities can subsequently be seeded directly onto them.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com