In a major development, the 3D printer manufacturer UltiMaker has launched a new improved version of its S series 3D Printers. The company offers an extensive range of 3D printing ecosystems including the MakerBot sub-brand and Sketch series. The new upgrade comes at a time when the company added PET carbon fiber 3D printing materials to the S series 3D Printers.

The company has enhanced the speed of its S series 3D Printers which will allow customers to double their print speeds and achieve 95% print success rates.

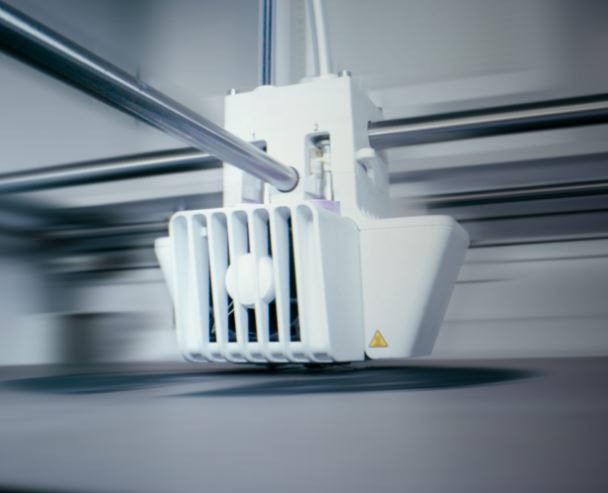

The UltiMaker S series 3D Printers is known to be the most versatile 3D printer in the market as it is compatible with more than 280 3D printing materials and has an ever-increasing portfolio of print profiles available from the UltiMaker Marketplace. The new S7 3D printer, the newest addition to the S series of 3D Printers has an integrated Air Manager which filters out 95% UFPs. The new 3D printer is powered by a new inductive print head sensor which makes it more accurate and less noisy. It also has a PEI-coated flexible build plate for easier print removal.

UltiMaker Cura has optimized its materials and print cores to accelerate the printing service provided to its customers with the S series 3D printers. The Cura 5.5 upgrade launched yesterday offers a range of optimized speed profiles which has been standardized across different line types. The S series 3D Printers are further fine-tuned so that they can be used with various print profiles and UltiMaker-branded materials, including PLA, Tough PLA, PETG, and ABS.

The company has also included some other improvements like the optimization of the material flow rates and nozzle pressures when switching between line types. This will ensure that customers don’t lose any print quality during transitions, and they achieve smooth internal wall pathing. With these new improvements, UltiMaker wants to reduce the problems of erratic infill motions which helps in smoothening the movement of the print head.

Speaking about the new speed improvement in the S series 3D Printers, the CEO of UltiMaker Michiel Alting von Geusau said that they are aiming to create “better experiences” for their customers and they believe “by optimizing the S series to speed up printing, our customers can accelerate returns on investment, enable faster time to market, and leverage the limitless possibilities of 3D printing”.

“We know that speed is only one part of the 3D printing success formula. UltiMaker printers have been trusted for years based on their reliability”, said Michiel Alting von Geusau.

The CEO underlined how the customers can use the new improved S series 3D Printers to shorten their development cycles and make faster design adjustments which will facilitate hands-on feedback from stakeholders. The new speed developments also make the production of 3D printed parts more agile, allowing for rapid response times to changing market demands. The supply chain resilience of AM parts will be boosted because of the on-demand digital inventory which reduces warehousing costs and prevents any disruptions.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com