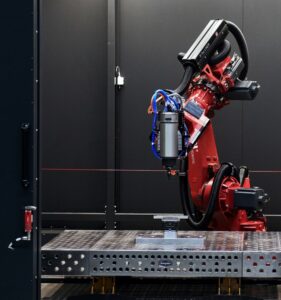

Among the wide range of services that technology solutions provider toolcraft delivers, there are robotic solutions. The German company introduces on the market two new robot applications that can meet the requirements of both AM and subtractive manufacturing processes.

The robot solution that will probably raise your attention as an AM enthusiast/user is a hybrid solution that can be used for both types of manufacturing processes. The company explains that the laser welding head can machine components using directed energy deposition (LMD/DED). This technique coats and adds new contours to existing components using selective material deposition.

Damaged and worn components can also be repaired by depositing material where it is required, with the laser-based and intricate welding process transferring very little heat into the workpiece. Besides saving costs, repairs use fewer materials than making new components and allow for combinations of materials that were not previously possible.

The robot from Mabi Robotic has a machining radius of 2.25 metres, making it suitable for both small and large components. In addition to “traditional” laser-powder deposition welding, extreme high-speed laser application (EHLA) deposition can be used to coat rotationally symmetrical components very efficiently, e.g. with a hard or wear-resistant coating. The adaptive motor spindle allows components to be pre-machined, welded and post-machined in a single clamping setup within the same robot system.

The switch from welding to milling is also fully automated without the need for any manual intervention. This allows surfaces to be prepared for the welding process, reference surfaces to be produced during the manufacturing process and surface finishes to be machined in further steps. With reachability of around two metres combined with a rotating and swivel unit as the machining table, the robot can be used for flexible, 8-axis manufacturing of complex geometries.

Comprehensive Siemens NX offline programming allows movements to be simulated separately from the manufacturing process and to be programmed using extremely precise path planning.

“The combination of two manufacturing processes in one robot cell is especially remarkable,” says Christoph Hauck, Chief Technology and Sales Officer at toolcraft. “It’s a true all-rounder that has the potential for many different extensions,” he adds.

Designed to enable automated milling, the other robotic solution is a 6-axis robot from Autonox Robotics GmbH that aims to set new standards in robot machining.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com