Together with software provider AMFG and provider of material and process validation services Additive Manufacturing Solutions Ltd, the Materials Processing Institute will develop an artificial intelligence tool that could lead to greater efficiencies within the Additive Manufacturing (AM) sector.

The £600,000 research collaboration is funded by Innovate UK, part of UK Research and Innovation (UKRI), the UK’s innovation agency, which drives productivity and economic growth by supporting businesses to develop and realize the potential of new ideas.

SMART-APP

Known as SMART-APP, the tool would provide a versatile, commercial, predictive material reuse management tool that will enable AM to expand by introducing greater cost efficiencies.

“SMART-APP aims to instill trust in the additive manufacturing realm by forecasting powder quality and recommending processes to restore desired powder properties for reuse,” Alexander Grimmer, Technical Consultant at London-headquartered AMFG said.

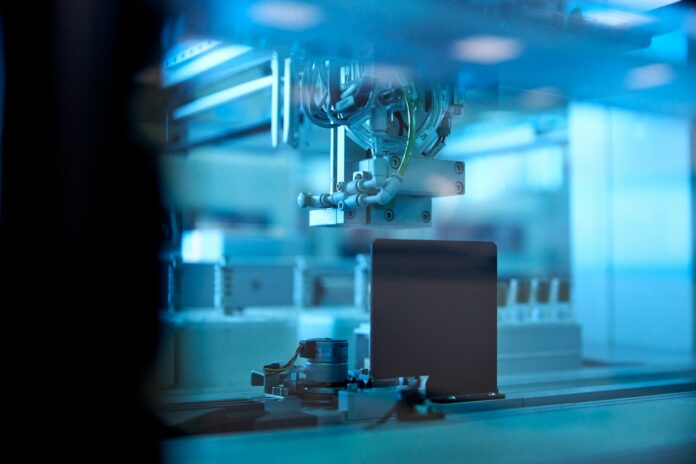

One area of particular interest is the growth of metal AM which is not yet cost-effective due to a development gap in the level of powder waste and length of processing time.

For this reason, the research will focus on the production of parts via Laser Powder Bed Fusion. SMART-APP would introduce smart predictive models for resource efficiency and waste reduction.

Simply put, SMART-APP aims to predict the quality change of the powder after each process and propose alternative process parameters on used powder to extend its lifespan with a minimal or an in-specification impact on product quality.

The research will feature materials characterization, and mechanical testing, investigating shelf life and the processability envelope of environmentally affected common stainless steel, titanium and superalloy base feedstock. It will also examine methods of reclaiming the powders and the effect on the final product.

The resulting outputs will be fed into an advanced database linking powder input properties against AM part performance to provide a predictive tool that will be available for the industry to use.

Nick Parry, Industrial Digitalisation Group Manager at the Teesside-based Materials Processing Institute, said: “SMART-APP is the next logical step to continue the work the Institute has already undertaken in powder characterization. By developing an artificial intelligence tool that can help AM users create faster and cheaper ways of maximizing powder reuse, the AM industry, especially those needing to maximize the operational effectiveness of their machines. This predictive tool will develop and enable world class production of AM components, with smart solutions for resource efficiency and providing longer use of materials feedstock and reducing wastage.”

Rob Higham, CEO of Additive Manufacturing Solutions, explains that this project marks their “first step towards a ground-breaking approach for dynamic materials management.” The AM process holds potential in many people’s eyes. “It could be realized with the development of a versatile and smart predictive tool for tracking powder quality after each reuse.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com