The Industry Sweden AB, a 3D printer manufacturer that develops FGF systems (fused granule fabrication), now provides its customers with patented bio-based and recyclable Sulapac materials.

Helsinki-based material producer Sulapac has developed materials that are made up of biodegradable biopolymers and sustainable fillers such as wood from industrial side streams.

Sulapac is just at the beginning of its 3D printing journey. Last year, the newcomer developed a wood-based filament made from a sustainable 3D printing material. The latter – named Eco-fil-a-GEHR – was used to produce thermoplastic semi-finished products manufactured by GEHR.

The recyclable 3D printing materials compatible with The Industry’s MAGNUM printers have a low carbon footprint, and would be safe for people and the planet throughout the lifecycle, with zero persistent microplastics or toxic substances left behind. They are also recyclable by design and can be made with recycled content.

“Thanks to the cooperation with The Industry, we have started to discover the variety of possibilities for Sulapac materials in 3D printing. Their technical fit and unparalleled sustainability features combined with the many benefits of 3D printing offer endless opportunities for companies willing to lead the way towards a cleaner future”, concludes Emmi Randell, Head of Business Development at Sulapac.

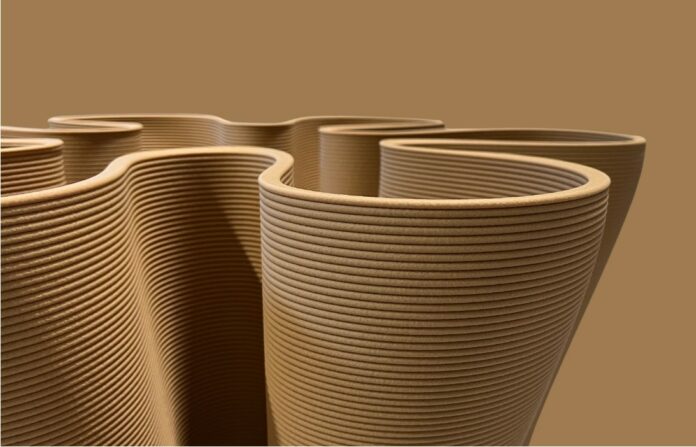

In addition to requirements for environmental responsibility, the materials selected for The Industry’s material library must fulfill strictly defined technical criteria. Sulapac Flow 1.7, a beautiful wood-composite, and Sulapac Universal Heat 30, a biobased material with good heat endurance and ability to stand high pressure, have performed excellently in the comprehensive testing conducted by The Industry, both in terms of mechanical properties and processability.

Both the Sulapac Flow 1.7 and Universal Heat 30 are food contact compliant and industrially compostable certified.

“In our experience, modern businesses are constantly searching for new materials that can convey a premium look and feel. After running multiple tests on our MAGNUM printer, we can say without a doubt that Sulapac managed to live up to the expectations and we can only foresee a positive increase in demand for their materials across various industries working with additive manufacturing technologies,” Jonas Carlsson, CEO of The Industry Sweden states.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com