Spatial Corp, a subsidiary of Dassault Systèmes, and ModuleWorks team up to provide CAD/CAM Solutions for Additive and Hybrid Machining.

Both companies are respectively known as provider of 3D software development toolkits (SDKs) for design, manufacturing, and engineering solutions for Spatial Corp, and supplier of CAD/CAM software development toolkits for machining and simulation for ModuleWorks.

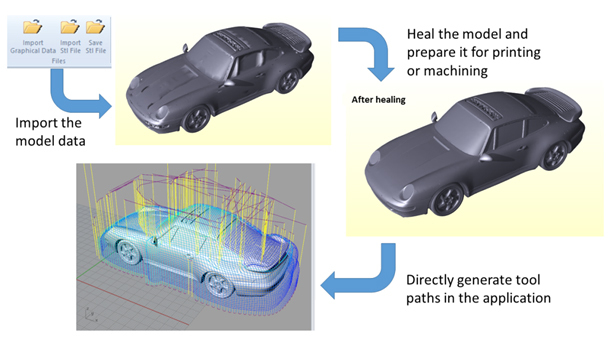

They developed SDKs (aka software components) that offer CAD/CAM vendors complete workflow solutions for additive and hybrid machining.

Spatial Corp’ clever platform, CGM Polyhedra SDK, which provides a suite of tools and capabilities to analyse, check and ensure the good functioning of polyhedral 3D models and the launch of the new high-performance additive components from ModuleWorks extend this cooperation into the field of additive and hybrid machining.

“We are looking forward to the launch of our new components for additive and hybrid machining,” said Mathias Rohler, Product Manager for Additive and Hybrid Machining at ModuleWorks. “Spatial’s CGM Polyhedra models provide excellent input data for our components. When used in combination, these libraries empower vendors with the tools they need to provide new, powerful, 3D printing solutions for end users.”

“Our continued cooperation with ModuleWorks will further enable us to deliver an integrated software platform to empower 3D printing OEMs and ISVs to create a single, comprehensive application, covering all the additive manufacturing software tasks,” said Ray Bagley, Product Manager for Modeling Products and Additive Manufacturing at Spatial.

“This integrated solution combines the power of 3D InterOp, CGM Polyhedra, and ModuleWorks machining engines. Customers will be able to leverage this solution to deliver much more robust applications to their end users, improving their user experience and production efficiency, all while reducing their own risk and getting to revenue faster.”

Last, this collaboration can only be successful since both companies have already experienced a successful cooperation a few years ago. Furthermore, this is the opportunity to ensure fast and flexible integration of libraries from both companies into CAD/CAM applications, spurring by this way the development of advanced, cost-effective workflow solutions for their customers.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!