Aerospace 3D printed part manufacturer Sintavia, LLC announced its single largest expansion in facilities and equipment since 2019. The $25 million investment includes additional advanced manufacturing space, large format printers, large format post-processing equipment, and component testing equipment. It is expected that with this investment, Sintavia will be able to meet the demand from the programs it supports across the U.S. Department of Defense for the balance of this decade.

“Looking into the next few years, it is clear to us that we need to make the investments today that will support the demand from our customers tomorrow,” said Brian Neff, Sintavia’s Founder and CEO. “As the world’s first truly all-digital aerospace component supplier, Sintavia is in a unique position to push the boundaries of what is possible in terms of designing and manufacturing next-generation aerospace components along a single, fully digital thread. But to do that, you must first have the right facilities, hardware, and software in place. That is what we are doing today in support of our customers and their critical programs.”

A major focus of the new expansion will be the continued design and development of high-performance thermodynamic components, in particular aerospace heat exchangers. Sintavia’s heat exchangers, which are enabled using additively designed triply periodic minimal surface structures, demonstrate improved heat rejection at comparative flow rates when evaluated against traditional versions. Additionally, the manufacturing sturdiness of a fully digital thread results in production yields close to 100%, multiples higher than manufacturing yields often experienced by traditional heat exchanger manufacturers.

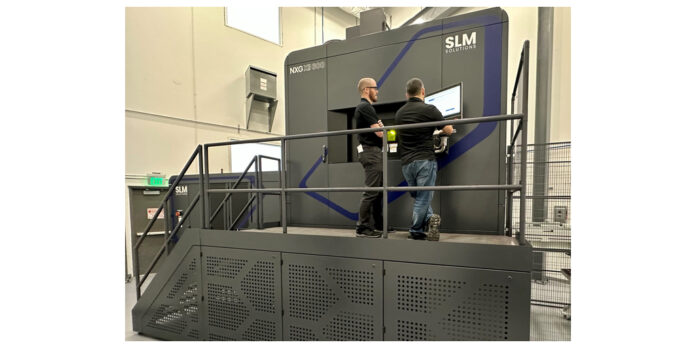

As part of the expansion, Sintavia signed a long-term lease on an additional 25,000 ft2 of manufacturing space adjacent to its existing headquarters, which it will use for printing, post-processing, and materials testing. New equipment included in the expansion includes Sintavia’s second SLM NXG XII 600, a third AMCM M4K-4, a second CT Scanner (450 kV), a second large air furnace, cold flow test machine, a shock and vibration table, pressure cycle testing equipment, acoustic testing equipment, multiple additional 5-axis CNC machines, multiple additional fatigue rigs, and multiple additional polishing machines. As it announced last October, Sintavia is also the North American launch customer for the AMCM M8K-K, the world’s largest industrially viable laser powder bed fusion printer, with an impressive cubic displacement of 38 ft3.

The expansion is expected to be completed by the fourth quarter of 2024.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com