The last time we checked, Sintavia was increasing its manufacturing capability with two M4K-4 Printers from AMCM GmbH. The US-based manufacturer of a wide range of flight and launch products continues to increase its manufacturing capability to meets the needs of the the Aerospace, Defense, & Space industry.

This time, it has added three more industrial 3D printers from GE Additive Arcam AB. The new Arcam A2X electron beam printers will complete the existing 4 EBM systems in the manufacturer’s facility.

From what we know, the A2X EBM printer has a build volume of 200 x 200 x 380 mm (x,y,z). Its build chamber could withstand extremely high process temperatures over 1100° C, removing this way residual stress while ensuring desired material properties.

“We are big believers in the electron beam process for high precision structural components manufactured in titanium,” said Brian Neff, Sintavia’s Chief Executive Officer. “It has been a great pleasure to work with GE Additive to develop successful manufacturing strategies for critical aerostructure components. We are excited to expand our production platform using the electron beam process in the months and years to come.”

The founder of AMGTA little communicates about the manufacturing of parts it achieves with its 3D printers. While this silence may be due to the confidentiality that often governs contracts between manufacturers and third-parties, we can’t help but think that the rise of its manufacturing capability can only be a good omen for the key verticals it targets.

Furthermore, apart from these additional industrial 3D printers, the company has also achieved various certifications for environmental management system as well as design & development.

The ISO 14001 approval for its environmental management system is meant for its Hollywood-based location. This accreditation is the third one Sintavia gets in the last five years; it demonstrates conformance to a set of environmental standards which include the scope of metal additive design and manufacturing as well as metrological and metallurgical testing.

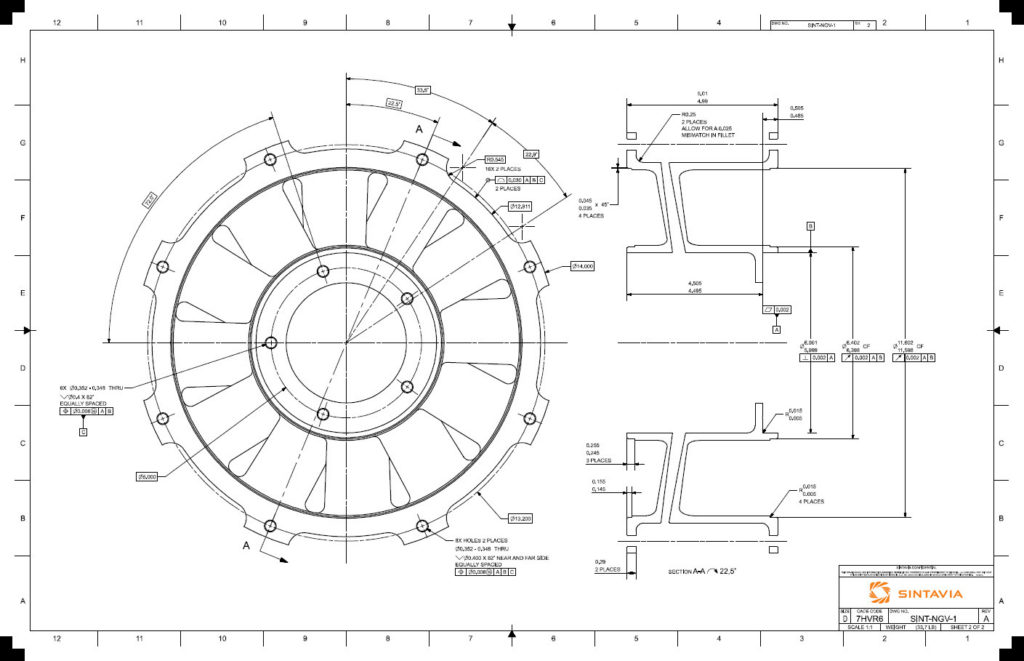

As for the AS 9100 certification, it is meant for product design and development. Delivered after months of auditing the company’s past performance, it ensures Sintavia’s ability to provide certified design solutions for critical components such as heat exchangers, combustors, and chassis.

In addition to these certifications, let’s remind that Sintavia is certified to ISO 17025 and holds Nadcap accreditations for laser additive manufacturing, electron beam additive manufacturing, and in-house heat treatment. In 2018, the company joined the Green Business Bureau (GBB) and has since earned the coveted GBB Platinum Level of certification.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com