As the name implies, a catalyst acts as booster – in this specific case, a booster of a chemical reaction without itself being part of the reaction. Shell is very good at developing catalysts to enhance the performance of petrochemical processes.

The team at Shell research centre explores the use of 3D printing in the development of new catalysts designs. They are traditionally manufactured using extrusion and pelletizing; processes that offer limited options for their shape and form.

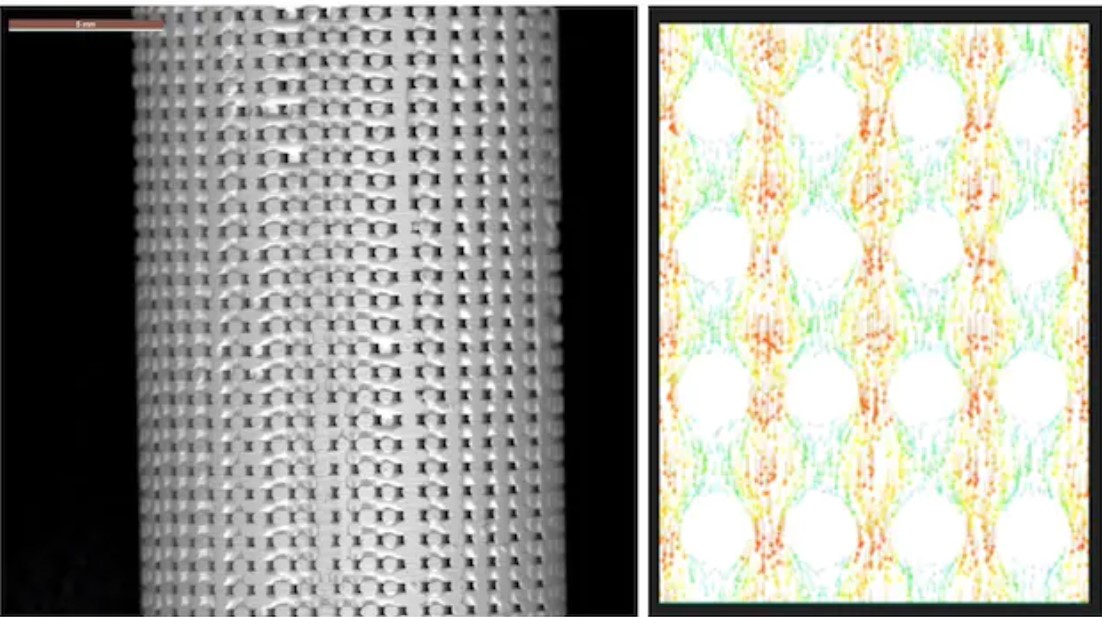

The requirements for efficient and high-performance catalysts extend beyond their macroscopic shape and form. Microscopic pores hidden inside a catalyst pellet are just as important as they provide high surface area essential in a catalytic reaction. With 3D printing, we can improve both macro- and microscopic designs of our catalysts.

With the support of 3D printing solution providers specialised in printing porous ceramic materials, the team prepared catalyst prototypes for their gas-to-liquids (GTL) technology and for environmental catalysis.

According to the team, AM helps to improve the desired properties of the final product such as catalyst activity and selectivity.

“3D printing is a key enabler to develop advanced catalytic materials which are crucial for the energy transition. This rapidly evolving field offers a myriad of opportunities to improve mass and/or heat transfers with better catalytic performance“, Ed Ganja, Vice President for Catalyst and Analytical Technology, Shell comments.

The future of 3D printing catalysts still has many opportunities and challenges. For example, we believe rapid catalyst prototyping via 3D printing will speed up the early stage of catalyst R&D considerably. The field of 3D printing technology is still advancing rapidly and commercial manufacturing platforms for 3D printed catalyst lie ahead, Shell states.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com