Roboze & Sabic, form the new duo “3D printer manufacturer & materials producer”. The collaboration of both companies results in the launch of a new high-performance 3D printing filament. Named EXTEM™ AMHH811F, the new material is designed for the Italian manufacturer’s ARGO Production 3D Printers.

Roboze & Sabic, form the new duo “3D printer manufacturer & materials producer”. The collaboration of both companies results in the launch of a new high-performance 3D printing filament. Named EXTEM™ AMHH811F, the new material is designed for the Italian manufacturer’s ARGO Production 3D Printers.

“To enable customers to print high quality parts for a range of demanding high heat applications, SABIC and ROBOZE have worked closely together to optimize print parameters and secure UL recognition for EXTEM™ parts printed on ROBOZE solution,” said Keith Cox, SABIC’s senior business manager for Additive Manufacturing.

“As a confirmation of this statement, the EXTEM™ AMHH811F filament has gained the UL Blue Card recognition with V0-075 certification on samples printed by ROBOZE ARGO Production 3D Printers with a thickness of 0,75 mm. This certification puts on the same regulatory level parts printed with FFF technology as the parts produced with traditional manufacturing like injection moulding.”

As a reminder, to enable the recognition of plastics intended for 3D printing, therefore to prove their safety, integrity and usefulness, UL launched the Blue Card Program earlier in the year. Therfore, it is in the best interest of 3D Printing materials suppliers to get a certification from UL, not to mention that all certified materials are added to the UL iQTM and UL’s Prospector® databases.

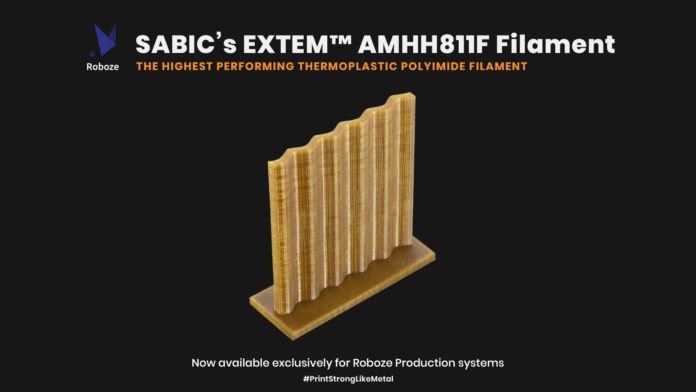

The EXTEM™AMHH811F filament

The EXTEM™AMHH811F filament is designed to meet the requirements of high performing parts in industries like motorsport, electrics, medical, aeronautics & space. Examples of applications include thermal and acoustic shields, enclosures for electronic components and sensors for electric vehicles.

Roboze & SABIC unveil a semi-transparent thermoplastic polyimide (TPI), that integrates flame retardant properties. Those properties, including the excellent dimensional stability and easy processability of the material, are maintained even with thin wall design. According to Roboze, the material can withstand great high temperature and deliver performance of heat deflection up to 230°C.

According to Roboze, the 247°C glass transition (Tg) temperature of EXTEM™ AMHH811F is the highest among all printable materials. Furthermore, the material is RoHS compliant and halogen free, according to VDE / DIN 472 part 815.

These properties position EXTEM™ AMHH811F filament as a new leading polymer capable of replacing metals in extreme applications.

This material will certainly be showcased at Formnext, alongside the new heat treatment process of the manufacturer.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media. For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com