UK-based Rivelin Robotics is known for its metal-AM post processing robotics solutions. The company along with the AM company Solukon is showcasing automated hardware solutions for the AM industry at Formnext 2023.

Ahead of the event, the CEO of Rivelin Robotics, Robert Bush writes about the importance of “hardware as a service” or HaaS, specially for the Additive Manufacturing industry.

The boom of software as a service or SaaS, which is used as a service commodity accessed via a subscription model, gave rise to a similar approach to hardware service contracts when AM companies try to scale up their in-house capabilities as it reduces expenditure.

However, automated hardware which is connected with manufacturing solutions like those used in the 3D printing industry needs a flexible revenue approach that supports HaaS with the necessary software for better productivity. This is necessary to facilitate between service contracts for automated hardware.

With automated manufacturing hardware like robots with the correct programming, the precision and consistency of metal-AM post-processing can be increased, leading to high-quality products. Automated hardware can also boost the production speed of the AM industry.

Various bottlenecks of metal-AM post processing like repetitive tasks and handling different dangerous tasks can be solved by using automated hardware. An automated additive manufacturing process can enhance workplace safety and save time.

HaaS is often used to speed up and reduce the costs of creating 3D-printed parts across various sectors like transport, racing, and agriculture. According to Rivelin, AM companies should leverage this with a flexible ‘pay-as-you-go’ revenue approach instead of using the traditional CapEx hardware purchasing model.

This will make HaaS a cost-effective solution for all AM companies irrespective of their size as they have to pay for the exact automated hardware services as long as they need them.

Through this 3D printing companies can align their costs with their needs which change according to market fluctuations. The ‘pay-as-you-go’ approach also lets the companies test the automated hardware before using them to scale up production.

HaaS makes the financial system of AM companies more transparent as large capital expenditures are replaced with monthly or quarterly payments.

HaaS also ensures that the automated hardware supplied by companies like Rivelin is well maintained and gets regularly updated with the latest software and other features, enhancing its efficiency and preventing hardware failures.

What we can expect from Rivelin…

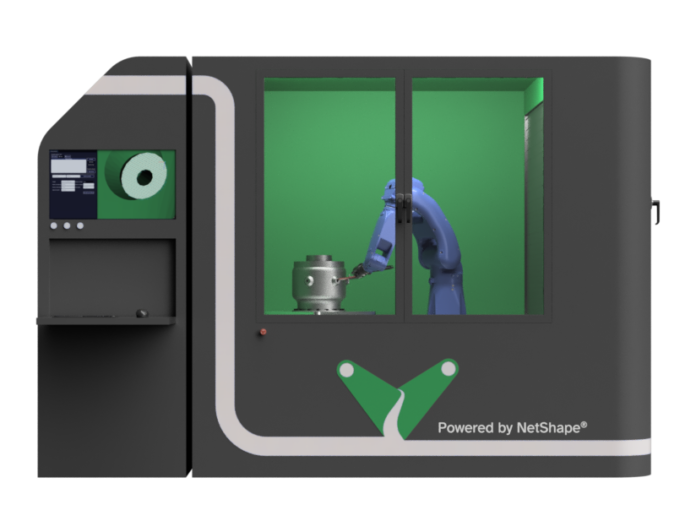

Rivelin insists on providing ‘Robots as a Service’ or RaaS which provides automated solutions for metal-AM post processing driven by their in-house Netshape® software drives which enables robots to carry out powder removal, base plate removal, support removal and polishing and finishing.

Rivelin Netshape® Robots tries to support AM companies throughout the 3D printing process including:

- NPI (New Product Introduction)

- Pre-Production Trials

- FAT (Factory Acceptance Tests)

- SAT (Site Acceptance Tests)

- In-Production and Post-Production Decommissioning.

The company is helping the AM industry with digital transformation by addressing its greatest challenges using a HaaS pay-as-you-go model that ensures cost-efficiency, scalability, and predictable budgeting for AM companies.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com