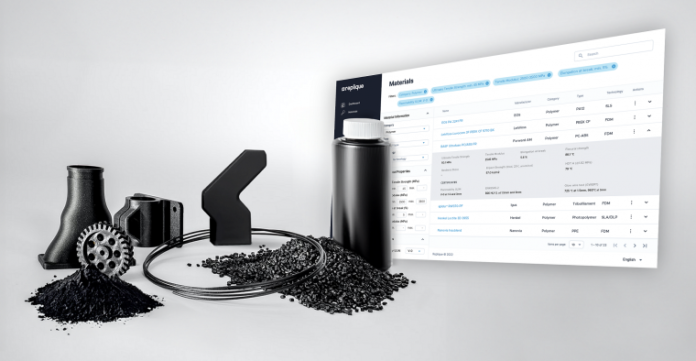

Replique, a provider of a decentralized 3D printing platform, has developed an open material database for Additive Manufacturing. The company aims to make the collective material knowledge accessible within the 3D printing community, ultimately streamlining the use of additive manufacturing (AM) across industries.

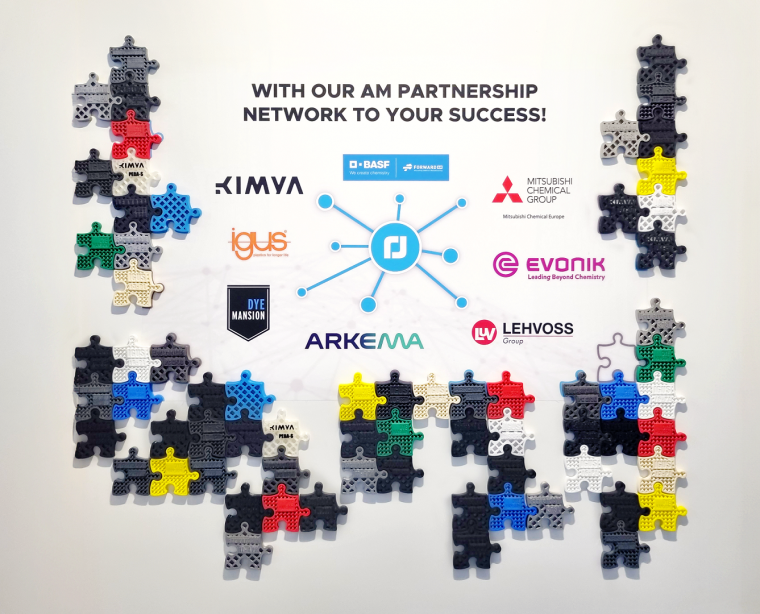

To do so, the company is working with trusted material partners such as Evonik, KIMYA, BASF, or even LEHVOSS to automate a research process that has been manual and labor-intensive for a long time.

Through an intuitive platform, users can select the ideal materials for their specific applications. The company explains that the database features various filtering options, including technical specifications, industry standards, and application fields. Additionally, it will offer quick access to reference cases and certificates in the future, eliminating the need for time-consuming inquiries. This data is the result of partnerships established with renowned material manufacturers in the past year.

Dr. Henrike Wonneberger, CEO, and Co-Founder of Replique, explains: “Through our daily engagement with material data, we have built a rich knowledge hub that we are now eager to share with the wider community. The launch of our material database represents another significant step in our mission to drive the industrialization of additive manufacturing and provide comprehensive support to our customers at every stage of their journey.”

Open material database for AM processes

The need for dedicated material database for AM has been raised as one of the main challenges Honeywell Aerospace in its AM journey.

Read more in the September/October edition of 3D ADEPT Mag (pp22-24): AM Shapers | Beyond LPBF: Honeywell on finding the right opportunity with Additive Manufacturing

Given Replique partners’ expertise one can understand that the company will focus (for a beginning) on polymer 3D printing solutions. In the AM, a similar initiative has been launched by Rosswag that is developing a LPBF process parameter marketplace that could accelerate the use of metal AM. It’s too soon to call it a trend, but given the complexity of material selection and the wide range of AM processes on the market, one should expect to see more material databases launched in the AM market.

It’s not just end-users who benefit from the material database. Printer manufacturers, service providers, and other interested companies can also leverage and contribute to the database, enriching their work and services with material insights. The advantage lies in the database’s design as an open system. As a result, the material data will be accessible not only through the Replique platform directly but also through an API interface in the near future. All data will be available behind a free password barrier for the convenience of all interested parties, Replique says.

It’s not just end-users who benefit from the material database. Printer manufacturers, service providers, and other interested companies can also leverage and contribute to the database, enriching their work and services with material insights. The advantage lies in the database’s design as an open system. As a result, the material data will be accessible not only through the Replique platform directly but also through an API interface in the near future. All data will be available behind a free password barrier for the convenience of all interested parties, Replique says.

Replique is committed to expanding the platform further with additional services in the future. In the meantime, the new material database can be explored for the first time at Replique’s booth in Hall 12.1, #A107, at Formnext.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com