Addicted to car technology and speed, Spyros Panopoulos is the founder of a company that wears his name. He ambitions to redefine the automotive scene by building a new category of cars which he wants “super-fast” and “connected”. Named Project chaos, the name of the project already sheds light on the expectations of the car manufacturer.

The official launch is expected for March 2021 but we can already share a bit of the manufacturing process of some parts.

The manufacturing of luxurious vehicles requires more and more the use of very expensive and unique materials as well as the use of additive manufacturing. Remember the 3D printed luxurious bike that was auctioned off to raise money for Australia’s bushfire victims or the $3.5M Bugatti Chiron Sport which revealed visible 3D printed parts such as its tailpipe.

Such type of vehicles is usually not mass produced given the uniqueness of their fabrication, which makes AM the ideal manufacturing technology for some of their components.

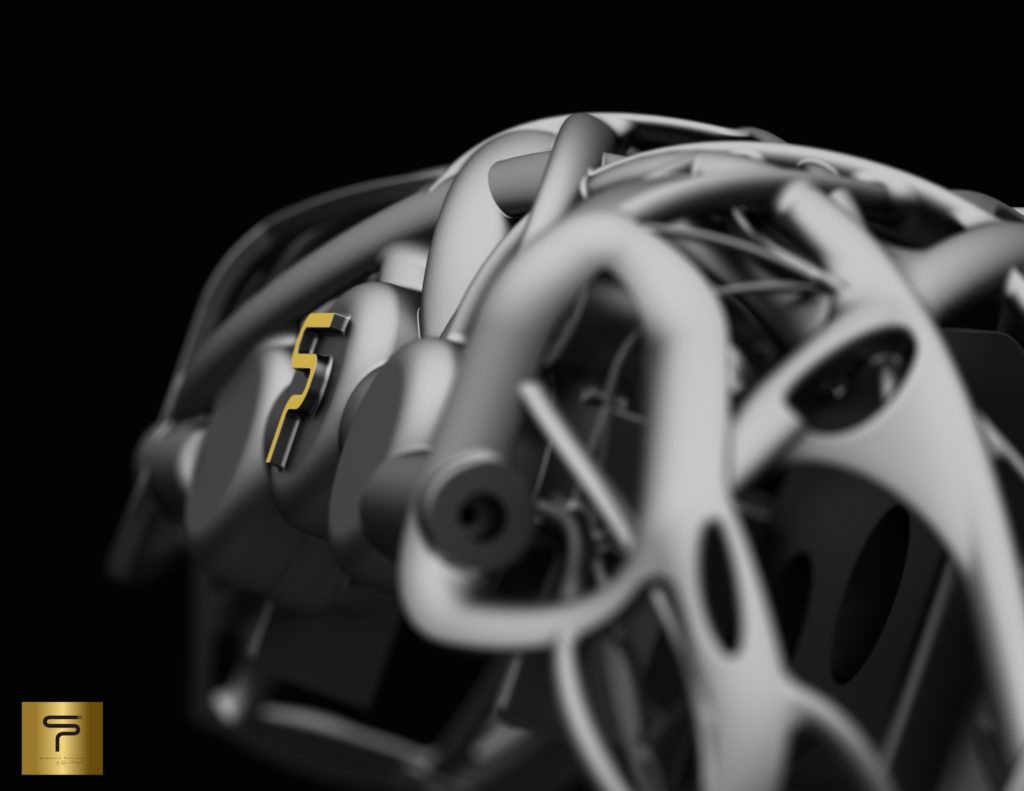

For this prototype, Panopoulos leverages additive manufacturing for several parts including pistons and rods, wheels, brakes as well as the chassis. The creator does not reveal the exact metal AM technology he leveraged, but we do know that by combining generative design and AM, he was able to use less materials and gain in performance.

Furthermore, Panopoulos would have developed his design method “anadiaplasi”. “By 2005 he had his own design and production unit of high-spec performance parts of cutting-edge technology for internal combustion engines, applying metallurgy and material mechanics in his research and development”, said the company on its website.

The method enables the component to take its natural shape depending on the forces in presence. The use of this method in this project would lead to the production of a car which might reach up to 400 km/h in about 7 seconds.

The company would showcase two versions of the car during the next Geneva Motor Show: both are both based on a 4-litre V10 engine which integrates 20 injectors and 40 valves. The first one would integrate 3D printed titanium pistons and connecting rods, running at a speed of 11,000 rpm while the second one should integrate carbon fibre connecting rods and pistons 3D printed with a ceramic material.

“A new term is needed because a new category is being born. It is called ultra-car. A car far more advanced than anything else out there. Something that will move and impress any car and speed enthusiast. From a simple driver to a race car driver. Faster than anything produced right now, more advanced in all areas, with new technologies and innovative materials. With a power to weight ratio which is close to 2:1, where for every 2 hp there is 1 kilogram of mass. With such a ratio mated to a suitable transmission technology, with the resulting adhesion, the driver will be able to experience accelerations up to 3G, for specific distances and conditions. The vehicle moving from A to B will need half the time needed by a hyper car or mega car. This may require the driver to have special driving skills and a better perception of space in order to reach the vehicle’s potentials. It will be produced in limited production numbers and will materialize in the rarest and most advanced materials that F1, aeronautics and space technology have to offer”, concludes the company.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com