A team of University of Colorado researchers has developed a new strategy for transforming medical images, such as CT or MRI scans, into incredibly detailed 3D models on the computer. The advance marks an important step toward printing lifelike representations of human anatomy that medical professionals can squish, poke and prod in the real world.

This development comes from a single observation: Surgeons have long used imaging tools to plan out their procedures before stepping into the operating room. But you can’t touch an MRI scan, said Robert MacCurdy, assistant professor in the Paul M. Rady, Department of Mechanical Engineering at CU Boulder.

His team wants to fix that, giving doctors a new way to print realistic, and graspable, models of their patients’ various body parts, down to the detail of their tiny blood vessels—in other words, a model of your very own kidney entirely fabricated from soft and pliable polymers.

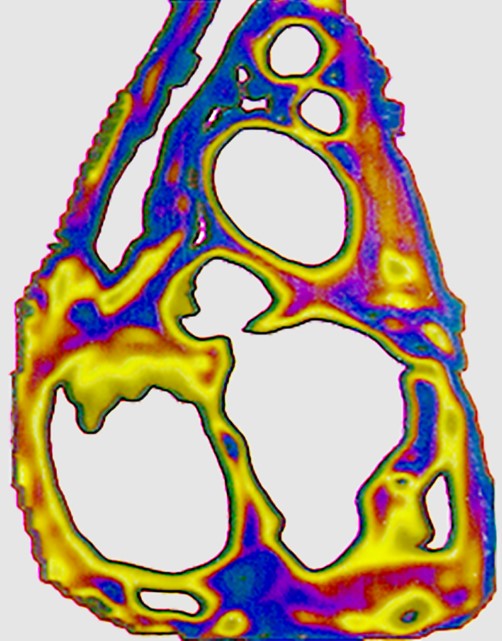

The latest study gets the team closer to achieving that goal. In it, MacCurdy – senior author of the new paper – and his colleagues lay out a method for using scan data to develop maps of organs made up of billions of volumetric pixels, or “voxels”—like the pixels that make up a digital photograph, only three-dimensional.

The researchers are currently experimenting with how they can use 3D printers to turn those maps into physical models that are more accurate than those available through existing tools.

The complexity of human organs

Human organs are complicated—made up of networks of tissue, blood vessels, nerves and more, all with their own texture and colors. Currently, medical professionals try to capture these structures using “boundary surface” mapping, which, essentially, represents an object as a series of surfaces.

“Think of existing methods as representing an entire orange by only considering the exterior orange peel,” MacCurdy said. “When viewed that way, the entire orange is peel.” His team’s method, in contrast, is all juicy insides.

The approach begins with a Digital Imaging and Communications in Medicine (DICOM) file, the standard 3D data that CT and MRI scans produce. Using custom software, MacCurdy and his colleagues convert that information into voxels, essentially slicing an organ into tiny cubes with a volume much smaller than a typical tear drop.

And, MacCurdy said, the group can do all that without losing any information about the organs in the process—something that’s impossible with existing mapping methods.

To test these tools, the team took real scan data of a human heart, kidney and brain, then created a map for each of those structures. The resulting maps were detailed enough that they could, for example, distinguish between the kidney’s fleshy interior, or medulla, and its outer layer or, cortex—both of which look pink to the human eye.

“Surgeons are constantly touching and interacting with tissues,” MacCurdy said, “So we want to give them models that are both visual and tactile and as representative of what they’re going to face as they can be.”

The project, which is led by MacCurdy and CU Anschutz’ Nicholas Jacobson, is funded by AB Nexus, a grant program that seeks to spur new collaborations between the two Colorado campuses. The entire paper was published on December, in the journal 3D Printing and Additive Manufacturing.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com